ADDITIONAL CALCULATOR NOTES:

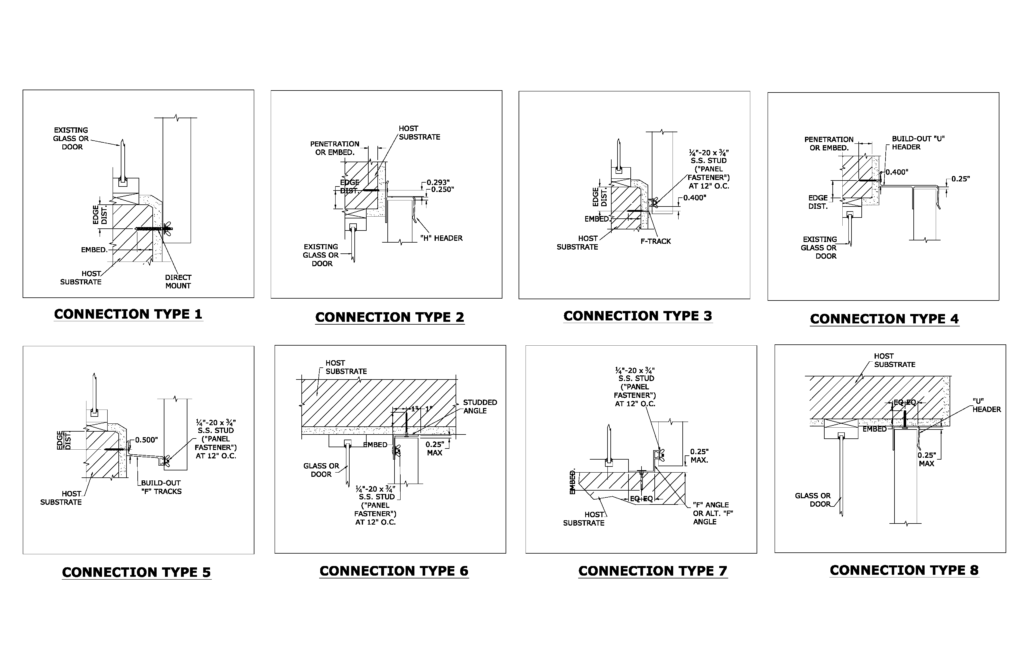

- “PANEL FASTENERS” ARE STUDS USED IN CONJUNCTION WITH ALL MOUNTING EXTRUSIONS (“F”-TRACK, STUDDED ANGLE, ETC.). “PANEL FASTENERS” SHALL BE SPACED AT 12″ O.C. ALL END PANEL HOLES SHALL HAVE PANEL FASTENERS, TYP.

- ANCHORS SHALL BE INSTALLED IN ACCORDANCE WITH MANUFACTURERS’ RECOMMENDATIONS.

- HOLLOW BLOCK HOST STRUCTURE SHALL CONFORM TO ASTM C90 BLOCK.

- MINIMUM EMBEDMENT AND EDGE DISTANCE EXCLUDES STUCCO, FOAM, BRICK, AND OTHER WALL FINISHES. WALL FINISHES SHALL BE LIMITED TO 1/4″ MAX OR SHALL BE VERIFIED BY OTHERS TO ADEQUATELY TRANSFER LOADS TO HOST STRUCTURE.

CONCRETE ANCHORS NOTED HEREIN SHALL BE EMBEDDED TO UN-CRACKED CONCRETE ONLY. - WHERE EXISTING STRUCTURE IS WOOD FRAMING, EXISTING CONDITIONS MAY VARY. FIELD VERIFY THAT FASTENERS ARE INTO ADEQUATE WOOD FRAMING MEMBERS, NOT PLYWOOD. FASTENING TO PLYWOOD IS ACCEPTABLE ONLY FOR SIDE CLOSURE PIECES.

WHERE ANCHORS FASTEN TO NARROW FACE OF STUD FRAMING, FASTENER SHALL BE LOCATED IN CENTER OF NOMINAL 2″ X 4″ (MIN.) WOOD STUD (3/4″ EDGE DISTANCE IS ACCEPTABLE FOR WOOD FRAMING). WOOD STUD SHALL BE G=0.42 OR GREATER DENSITY, U.N.O. LAG SCREWS SHALL HAVE PHILLIPS PAN HEAD OR HEX HEAD. - REMOVABLE ANCHORS ARE: ELCO PANELMATE, ALL-POINTS SOLID-SET.

- MACHINE SCREWS SHALL HAVE 1/2″ MINIMUM ENGAGEMENT OF THREADS INTO THE BASE ANCHOR AND MAY HAVE EITHER A PAN HEAD, TRUSS HEAD, OR WAFER HEAD (SIDEWALK BOLT) U.N.O.

- MINIMUM EMBEDMENT AND EDGE DISTANCE EXCLUDES STUCCO OR OTHER WALL FINISHES.

| MINIMUM POLYCARBONATE PANEL PROPERTIES FOR USE WITH THIS APPROVAL: | ||

| SPECIFIC GRAVITY | 1.20 G/CC | ASTM D792 |

| TENSILE YIELD STRENGTH | 8700 PSI | ASTM D638 |

| FLEXURAL STRENGTH AT YIELD | 12500 PSI | ASTM D790 |

| FLEXURAL MODULUS | 340000 PSI | ASTM D790 |

| NOTCHED IZOD | 18 FT-LB/IN | ASTM D256 |

| SMOKE DENSITY | 75 MAX | ASTM D2843 |

| RATE OF BURNING | C1 CLASS MAX | ASTM D635 |

| SELF IGNITION | 650 DEG. F | ASTM D1929 |

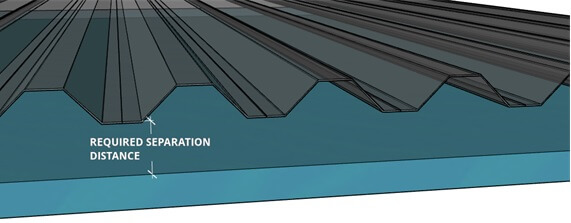

Separation From Glass Defined

See Calculator or Product Approval for applicable distance for your project

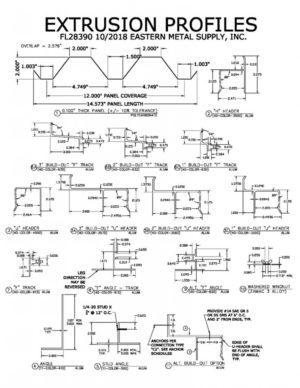

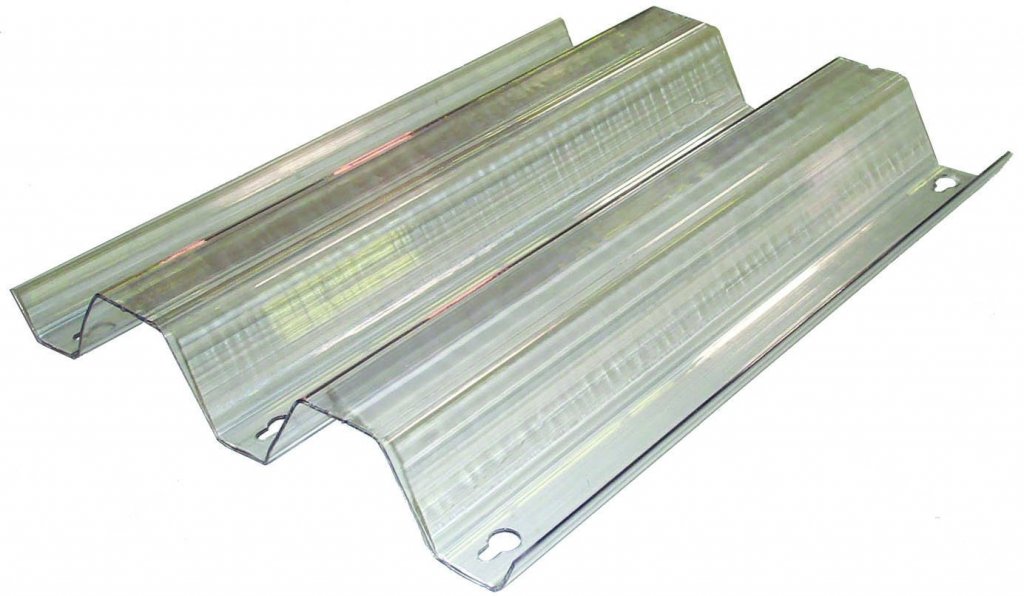

Extrusion Details

Product Brochure

Digital product approvals were conceived, created, and maintained by Engineering Express. This product evaluation is the first in history to have a digitally assisted counterpart as part of the evaluation document. It complies with F.S. 553.8425 and 61G20-3 that permit modifications to a product evaluation if certified by a professional engineer. Digital content also expands the understanding of the product as well as research, ordering, and understanding of related parts and accessories.

FS 553.8425 (3):

Local building officials may accept modifications to approved products or their installations if sufficient evidence is submitted to the local building official to demonstrate compliance with the code or the intent of the code, including such evidence as certifications from a Florida registered architect or Florida professional engineer.

Information regarding the necessity of listing all extrusions and material specifications was brought to the FL POC at their August 14, 2018 meeting. It was concluded by the POC that the level of information listed on submittals such as the digitally assisted approval are within statutory compliance. Click here for information on that meeting