When A Glazed Opening Isn't Exactly Square

Often times a glazing product is approved for large missile impact, but requires a field modification for size.

While the tested span cannot be exceeded and still meet the building code’s large missile impact requirements, the aspect ratio (the length to width ratio) can be altered so long as the glass area does not exceed the tested size.

The maximum aspect ratio of the length to width in glazing within the HVHZ is 5:1.

See this link to the Miami-Dade website explaining the Aspect ratio requirements.

Keep all of the Larger dimensions / Smaller diminsions below 5 so the comparative analysis will fall within the ASTM E1300 requirements.

If the aspect ratio exceeds 5 and the client wants to include it in a Florida Product Approval, then additional glass units should be tested using the requested Glass unit size.

Understanding the 'Bounding Box'

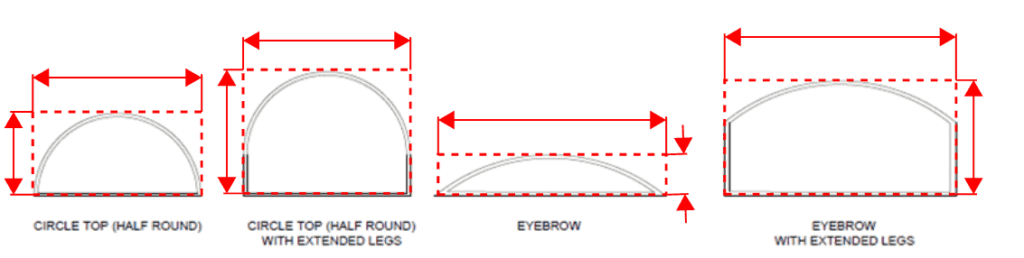

Sometimes glazing units are not rectangular or square.

Use the below image as a guide to understanding the general theory of measuring glass unit sizes and aspect ratios for your comparative analysis.

Always seek the advice of a design professional prior to installing any shape outside of Miami-Dade or Florida Product Approval specifications.

Find Approved Glazing Products

Find Florida & nationally approved glazing products for use in construction at EngineeringPlans.com.

Last Update: March 27, 2025

Related Knowledge Base Posts -

- Should a professional utilize the ASD (“Allowable Stress Design”) method or the LRFD (“Load Resistance Factored Design”) method when calculating the required wind pressure for use with tested / approved systems?

- What wind speed should I use for my project?

- ASCE 7 WIND EXPOSURE CATEGORIES AND HOW EXPOSURE ‘D’ WORKS

- What is a window or door buck

- What are the requirements for using ASTM Missile Level E in Florida (2021 updated)?

- How do I calculate the effective opening area on window or door products? – What opening area should be used for wind pressure determination on a multi-panel product?