Lag screws are some of the toughest types of screws available. When it comes to fastening heavy materials in construction and woodworking, lag bolts and lag screws stand out as some of the most reliable and commonly used fasteners.

In this article, we’ll take a closer look at why they’re so widely used, exploring their uses and features. We’ll also discuss building code specifications for lag screws, covering their engineering uses and how to meet industry standards.

Understanding Lag Screws

Lag Screws vs Lag Bolts

Lag screws and lag bolts are terms frequently used interchangeably, but they actually refer to the same type of fastener. The terminology can vary by region and industry; for example, “lag screw” is often preferred in woodworking contexts, while “lag bolt” is more commonly used in construction. However, the most accurate term is “lag screw,” as it correctly reflects the fastener’s design, which does not require a washer or nut.

Why choose Lag Screws?

Lag screws are primarily used for fastening wood, thanks to their self-tapping design that allows them to create strong connections without needing to pre-drill holes in most cases. However, larger lag screws may require pre-drilling to ensure proper installation. They are sturdy, tough, and reliable, making them a favorite in construction and woodworking projects. You’ll often find lag screws used to secure timber beams, build decks, and assemble heavy-duty furniture where strength is essential. Their coarse threads grip the wood tightly, ensuring that everything stays stable and reduces the risk of loosening over time.

While lag screws can work with other materials like metal and concrete, they shine the most when used with wood. Many of them also come with protective coatings to prevent rust, making them perfect for outdoor projects exposed to moisture and weather. Overall, lag screws are a dependable choice for anyone looking to create durable, long-lasting connections in their building projects.

Design features

Lag screws are designed with distinct features that enhance their performance as heavy-duty fasteners. They typically have a hexagonal head, which allows for easy installation using a wrench or socket, providing the necessary torque to securely drive the screw into the material. One notable characteristic is that the threads on lag screws are coarse and often do not extend all the way to the head. This design allows the screw to grip the material effectively while providing a smooth, unthreaded section near the top, which can help prevent splitting in the wood and allows for a better fit in certain applications. The pointed tip enables lag screws to penetrate wood easily without the need for pre-drilling, streamlining the installation process.

Lag Screws vs Wood Screws

Lag screws have significant advantages over regular wood screws, especially when it comes to handling heavy loads and creating strong connections. While regular wood screws have finer threads and are designed for lighter tasks, lag screws boast coarser threads and a thicker shaft, which helps them grip the material more securely. This makes lag screws perfect for jobs that need extra strength, like securing large beams or heavy structural connections. Plus, their hexagonal head allows you to use a wrench for greater torque during installation, whereas regular wood screws are typically installed with a screwdriver. In summary, if your project requires enhanced durability and the ability to bear heavy loads, lag screws are the way to go, while regular wood screws are best for everyday tasks.

Lags in use

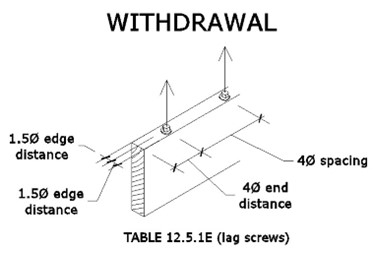

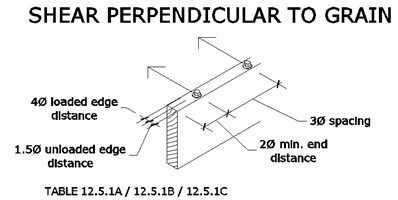

Using lag screws to fasten sheathing to multi-ply wood columns can be tricky, especially when it comes to positioning the screws in relation to the edges of the wood. This placement is crucial because it affects the screw’s performance, as outlined in the NDS (National Design Specification) tables 12.5.1A, 12.5.1C, and 12.5.1E, which detail the minimum edge and end distances required for proper installation. A key concern with larger diameter bolts is the risk of splitting the wood before the load can shift to other bolts that are less heavily loaded. For example, when using lag bolts in tension on a narrow face of a 2x wood piece, table 12.5.1E indicates that you need to maintain an edge distance of 1.5 times the diameter of the screw and an end distance of 4 times the diameter. So, for a ½-inch diameter lag screw, you should have a minimum edge distance of ¾ inch. This ensures that the fastening is effective while also protecting the wood’s integrity.

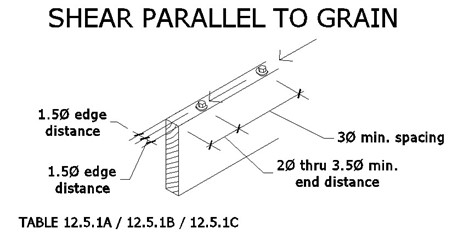

When using lag bolts in shear with loads parallel to the grain on the narrow face of a 2x wood piece, you’ll want to pay attention to the edge and end distances outlined in the NDS tables. According to table 12.5.1C, the minimum edge distance should be 1.5 times the diameter of the fastener, while table 12.5.1A suggests that the minimum end distance can range from 2 to 3.5 times the diameter. For a ½-inch diameter lag screw, this means you need at least a ¾-inch edge distance. Following these guidelines ensures that the lag screws can be used effectively while maintaining the wood’s integrity under shear loads.

The situation changes when the same lag bolt is loaded perpendicular to the grain. According to table 12.5.1C, the edge that bears the load needs to have a minimum distance of 4 times the fastener diameter. For a ½-inch lag bolt, this means you need at least 2 inches of edge distance, while a 3/8-inch lag bolt requires 1.5 inches. This requirement exceeds the ¾-inch edge distance that would be available if you were able to center the fastener in the narrow face of the 2x wood. This highlights the importance of careful planning when placing lag bolts to ensure they meet the necessary structural guidelines.

To understand how to position lag screws effectively, it’s important to distinguish between the loaded and unloaded edges of the beam (or stud, in this case). The loaded edge is the side that faces the direction of the force, while the unloaded edge is the opposite side.

For more detailed information, the NDS provides specific guidelines on end distances, edge distances, and other critical designs for lag bolt connections.

Now that lag screws hold no secrets for you, we wish you the best of luck with your upcoming projects! If you have any questions about wood design or need engineering assistance, simply click the button below to get in touch with us. Don’t forget to explore our other engineering articles on our website for more valuable insights and tips!

Contact us with your wood connection needs to discuss our innovative engineering solutions

Last Update: November 11, 2024