Summary of Building Code & Research Intent

The intent & provisions of the 2018 International Building Code (IBC), 2018 International Residential Code (IRC) & 2020 Florida Building/Residential Codes are to establish minimum

requirements to safeguard the public safety, health, and general welfare of occupants of new and existing buildings & structures.

From 2022 / 2020 FBC, 8th/7th Edition, Chapter 1 [A]101.3 Intent.

The purpose of this code is to establish the minimum requirements to provide a reasonable level of safety, public health and general welfare through structural strength, means of egress facilities, stability, sanitation, adequate light and ventilation, energy conservation, and safety to life and property from fire and other hazards attributed to the built environment and to provide a reasonable level of safety to fire fighters and emergency responders during emergency operations.

While not ideal, the safety & well-being of the public comes first as a code-minimum standard.

The building codes relate to the design of mechanical equipment, whether part of the building envelope or outside & not part of the building envelope.

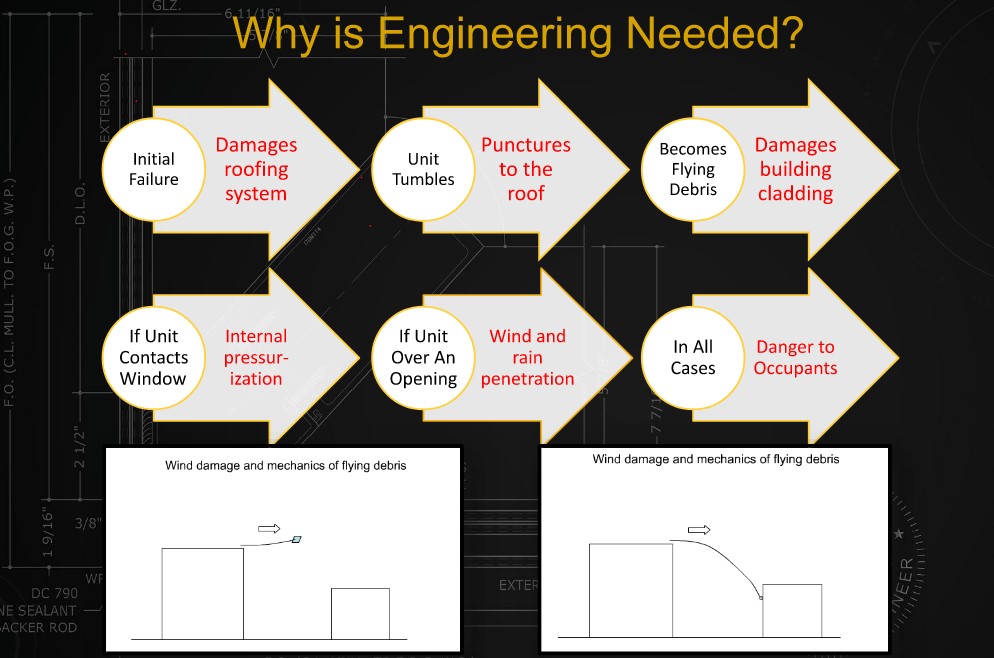

* The safety & welfare of the public is compromised when a mechanical unit jeopardizes the integrity of the building envelope. This occurs when a rooftop unit is dislodged & an opening in the rooftop creates building envelope internal pressurization or a rooftop or ground-mounted unit disassembles during a wind event & creates flying debris which can jeopardize the integrity of surrounding buildings (see graphic).

The wind design of mechanical units follows Chapter 16 of the Florida or International Building Codes (2020/2018 linked respectively). Specific attention is drawn to loading on ‘other structures’, which is a separate design component of ASCE-7 (Chapter 29, ASCE 7-16). Section 29.4 relates to ground or roof-mounted unit wind design. Section 30.10 describes rooftop structures & equipment design for buildings & explains forces shall be considered to act inward & outward on the surface wall and in upward directions.

This design does not define deflection or permanent-set limits after a wind event but implies integrity must be maintained of the unit as a whole.

Additionally, the 2020 Florida Building Code defines in Chapter 28, Mechanical Systems – Mechanical Code Section 301.15 Wind resistance. Mechanical Equipment, appliances & supports that are exposed to wind shall be designed & installed to resist the wind pressures determined in accordance with the Florida Building Code, Building (with exceptions).

Additional publications which further define the minimum standards of design include:

- AHRI 1310p, which states Section 1.1.1 Intent. This standard is intended to provide guidance regarding the minimum requirements of exposed equipment cabinetry to safeguard surrounding elements from windborne debris damage through structural strength to resist wind forces that cause overturning, sliding or separation of unit components.

- See also Florida House Bill 535 663, 704 (FS 5523.844) Senate Bill SB 1040 for additional certification requirements & limitations as they pertain to requirements of design in Florida.

- See also ASHRAE Journal, Vol 48, No 3. P 36-43. Reinhold, T.A. (2006) Wind Loads & Anchorage Requirements for Rooftop Equipment

- See also IBHS “Wind Loads on Small Roof-Mounted Air Conditioning Units”, Morrison, Murray J., Ph.D. (2013) (Insurance Institute for Business & Home Safety)

- See also Journal of Wind & Engineering, “Wind Loads Rooftop Equipment Mounted on A Flat Roof” 8(1), 23-41, Erwin, J.W., Chowdhury, A.G. & Bitsuamlak, G. (2011)

- See also “Wind Loads on Roof-Mounted Cube (BLWT-SS47-2007), London, ON, Canada, The Boundary Layer Wind Tunnel Laboratory, Kopp, G.A. & Traczuk, G. (2007).

The Code is to be a minimum requirement that is flexible and affordable. It isn’t intended to inhibit competition and it should promote innovation and the use of new technology. The primary goal is the minimum standards for public health and safety. The secondary goal is for the protection of property.

What Engineers Certify With Performance Evaluations

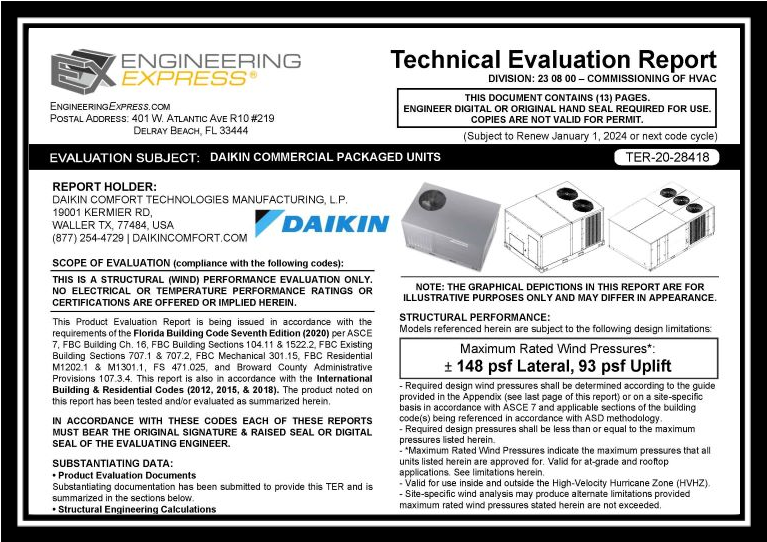

Performance Evaluations are a generic code-minimum requirement for installing mechanical units (air compressors, package units, generators, etc). They establish a maximum static-force pressure rating (typically in ASD, allowable stress design as noted on the evaluations) that the cabinet in question can theoretically withstand at the time of installation per the above-referenced codes & standards. This evaluation is based on a combination of recognized testing & rational analysis for the overall diaphragm, each panel component, and unit tie-down.

The maximum pressure rating establishes a performance baseline under which the unit can adequately resist the imposed static wind loading without experiencing failure of the unit cabinetry or tie-down system, as defined in the evaluation.

If the unit is designated for an essential facility, it must also pass large missile impact testing & certification. Missile Impact is a test-only phenomenon that is governed by ASTM E1886 & ASTM E1996.

Per FBC 453.24.5:

Electrical & standby emergency power systems… When generators are installed, the facility housing the generator, permanent or portable, shall be an enclosed area designed to protect the generators from wind & missile impact. Generators hardened by the manufacturer to withstand the area’s design wind & missile impact criteria shall be exempt from the enclosed area criteria requirement.

In the Florida Building Code 2020 section 1626.1.d – an exemption states that HVAC equipment does not require impact protection for “standard facilities.

Refer to our article on missile impact requirements for mechanical equipment in essential facilities by clicking here.

This exemption means that generators for residential units do not have to go through testing & impact certification & are subject to damage & dislodgement when impacted with design-force impact debris. Our Technical Evaluation Reports make it clear that certification of the unit does not apply to systems subjected to impact forces. Consequently, the unit’s operation is not guaranteed after a design event.

What Isn’t Covered Within Performance Evaluations

In addition to static load, non-impact limitations of non-essential facilities & the certification for missile & wind forces within static facilities, it is critical to understand that performance evaluations do not comprise a certification of any

system or unit at a site-specific location.

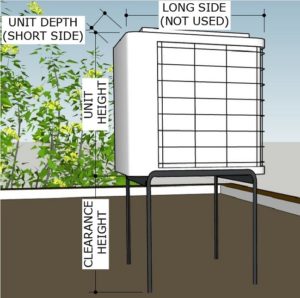

A Design Professional (such as a licensed professional engineer or registered architect certified to practice within the state of the project location) must determine the site-specific conditions to interpret the design wind velocity and resulting wind pressure(s) acting on the unit in question. Factors such as the installing height from grade, geographic exposure, flat/hilly terrain (escarpment), the geometry of the unit, unit location relative to the roof layout, and vortex-contributing factors, among others, all contribute to the wind velocity-to-pressure conversion. Using a sealed TER without a design professional’s site-specific review is a violation of the code and does not constitute acceptable engineering for permit or installation.

Engineering Express publishes a rooftop equipment wind velocity to pressure calculator to demonstrate these variables for design professional estimation. We also publish a Forces Guideline Page to assist in adapting the results to a site-specific condition as a public service.

Important Limitations of Use & Code Compliance

In addition to specifying the installation conditions for wind pressure certification, Technical Evaluation Reports specify that the manufacturer, installing contractor, and end-user collectively have responsibilities for maintaining performance as well. These limitations may or may not be directly incorporated in the evaluation report or contract documents but are within communication with the client and indirectly referenced herein via the URL & QR codes found on reports. These include:

Survivability:

Evaluation reports are valid for a newly installed unit and do not include certification of the product beyond a design event if impacted. Inspections shall be implemented during annual equipment maintenance or after a named storm. All fasteners and cabinet components are to be verified, and all damaged, loose, corroded, and/or broken fasteners and cabinet components shall be replaced to ensure structural integrity against hurricane wind forces. Contact this office for any reevaluation needs as designated by the Authority Having Jurisdiction.

Durability:

Components or component assemblies shall not deteriorate, crack, fail, or lose functionality due to galvanic corrosion or weathering. All supporting components that are permanently installed shall be protected against corrosion, contamination, and other such damage at all times. Each component or assembly shall be supported and oriented in its intended installation position. All exposed plastic components shall be certified to resist sunlight exposure as specified by ASTM B117 or ASTM G155 in Broward or Miami-Dade counties.

Extent of Certification:

Certifications pertain to the structural integrity of the unit components listed within the evaluation, subject to the limitations and criteria stated therein. Operability and water infiltration are outside the bounds of this certification. No other certifications are intended. This evaluation alone does not offer any evaluation for large missile impact debris or cyclic wind requirements unless specifically stated within the evaluation.

UNDER NO CIRCUMSTANCE DO ANY OF OUR PERFORMANCE EVALUATIONS GUARANTEE, IMPLY, OR STATE THAT THE PERFORMANCE OF THE UNIT IS MAINTAINED DURING OR AFTER A DESIGN EVENT.

* Items in bold-italic represent the opinions of this firm, and while it is of the opinion of the firm that they are adequately researched & documented, they do not describe facts or necessarily refer to specific code compliance.

Last Update: February 15, 2024