FREQUENTLY ASKED QUESTIONS

Our FAQ includes common company questions, online plan & site-specific job ordering.

Also Visit Our Knowledge Base

Search our entire Knowledge Base, a library full of engineering & code related articles.

Switch to Article Mode

Models

Ordering – Payments – Tokens – Delivery – Subscriptions & Memberships 26

How can I pay for something custom that’s not a store product or something quoted?

Tell us how can we improve this post?

How To Use Master Plans – TER’s – Calculator Reports Purchased From Engineering Express

READ BELOW BEFORE USING NON SITE-SPECIFIC PERFORMANCE EVALUATIONS

FROM ENGINEERING EXPRESS FOR YOUR PROJECT

General Information About Non Site-Specific Plans:

Certified Performance Evaluations (also referred to as Master Plans, Generic, or Non Site-Specific Plans) you receive contain a physical or digitally certified engineer seal. They are intended to be used to assist in obtaining a building permit and in constructing the component conveyed in the plan. In all cases using a non-site specific plan, additional documentation is required to serve as approval of use of the purchased document for the intended location. The design professional providing that approval then becomes the responsible party for their use at that location. This additional documentation is provided by others and not part of the purchase of master plans or technical evaluation reports (TER’s) from us.

At no time is construction to be performed without the review and approval by another party of the documents purchased regarding the applicability, limitations of use, and proper selection of plan detail options for the intended installation. In all cases, completed work shall be inspected and approved by others before approval for use including but not limited to the municipality having jurisdiction, architect and/or engineer of record, and permitting contractor which is not our responsibility or part of this purchase.

The documents you purchase from us unless otherwise stated are for sole approval of a pre-engineered, non-site-specific building component subject to the stated limitations of use only and are NOT intended to serve as approval for the construction of any design or installation.

ALSO, AT NO TIME IS ANY PHOTOCOPY OR UNSEALED DOCUMENT TO BE USED OF PLANS FOR PERMIT UNDER ANY CIRCUMSTANCES. BUILDING CODES REQUIRE AN ORIGINAL, CERTIFIED DOCUMENT FOR EACH PERMIT TO BE VALID FOR USE.

Using Certified Master Plans, TER’s & Other Evaluation Reports

The Master Plans & Technical Evaluation Reports (TER) we provide are structural performance evaluations of the subject building component and do not contain a site-specific address. The certification of those documents approves the limitations of use as stated, NOT that the building component can be used at a specific location. That is the responsibility of others as described herein.

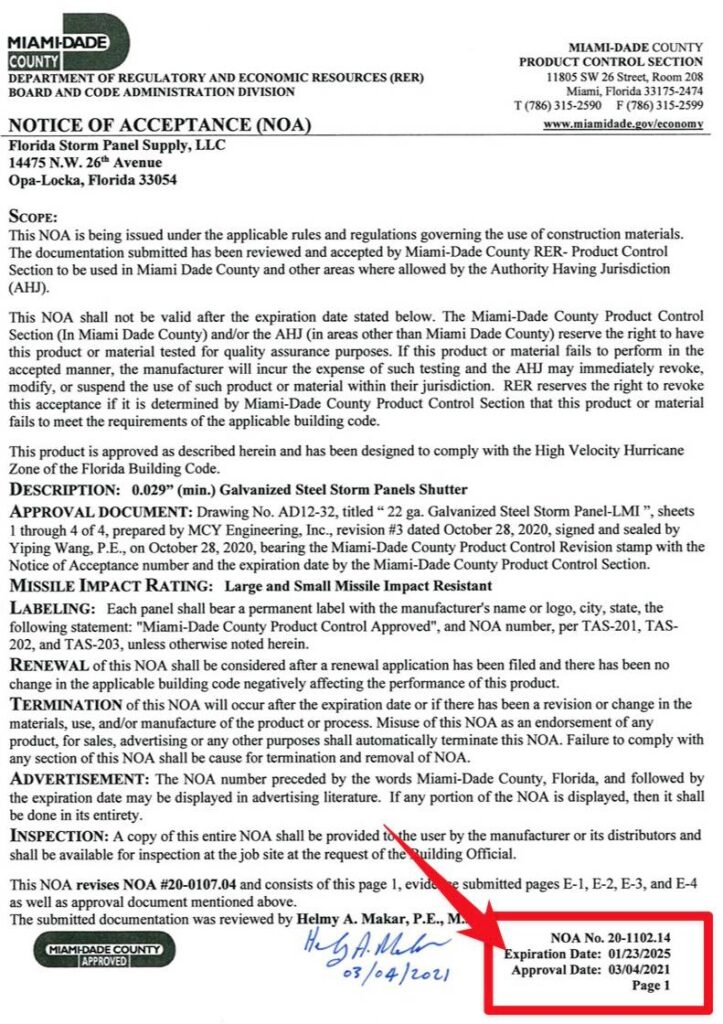

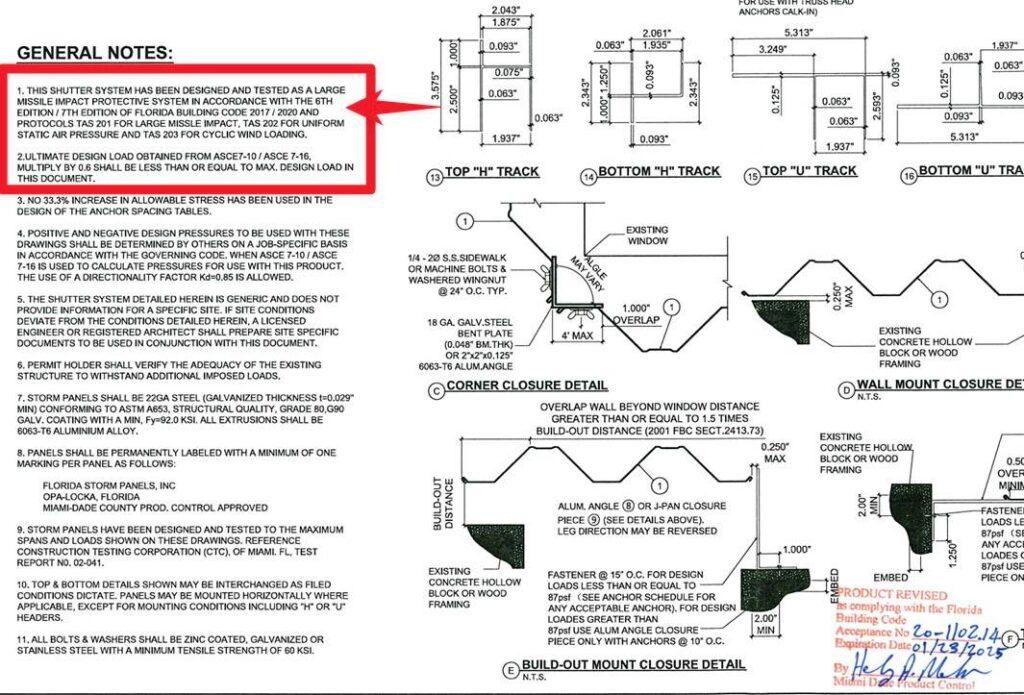

THIS ALSO INCLUDES THE USE OF PERFORMANCE EVALUATIONS SUCH AS MIAMI DADE NOA’S, FLORIDA PRODUCT APPROVALS, TEXAS TDI EVALUATIONS, & ICC EVALUATION REPORTS.

The user of the original, certified documents (never photocopies) shall carefully review each detail for applicability to their site-specific condition and gain approval of use for their application by others. Engineering Express remains available for questions via email, online chat, or phone for questions or clarifications of the information within the purchased document and as contained herein which may result in additional engineering consultation fees. Site-specific review and approval and customized & site-specific design plan services are also available which can be performed by this office or another licensed professional.

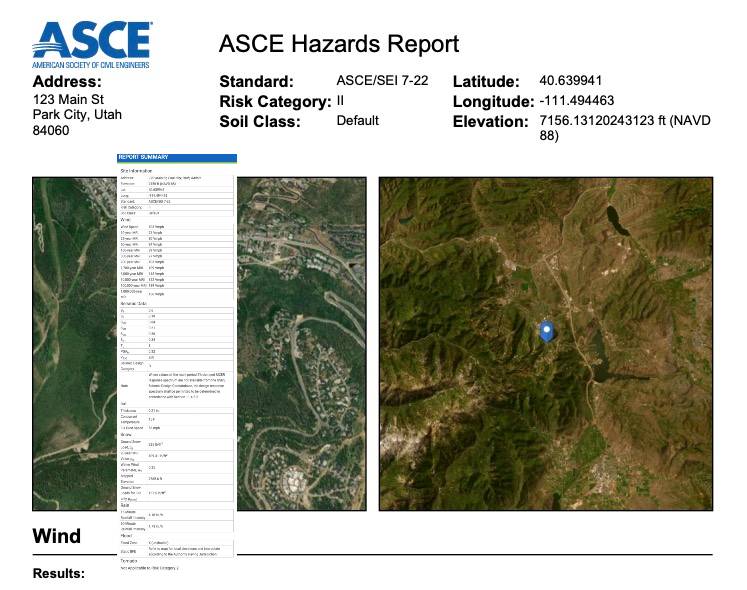

Using Certified Design Calculator Reports With Addresses Generated By Engineering Express

Printouts from online calculators may come with a site-specific address. It is understood and agreed that the address, as well as all inputted information, is provided by the purchaser at the time of purchase. By agreeing to purchase the document, you understand and affirm that we have not been contracted to a site-specific study, field investigation, or review design plans by others to provide the result you purchased. The site-specific address you provide serves to bind the document to your permit as is required by code and does not constitute that a site-specific or field review has been performed by this firm to authorize their use. The documents also contain information explaining this, as well as the fact that the certified results are to be reviewed by a design professional along with other required construction documents to obtain a permit for construction and use.

The information provided in the purchased document shall at all times be reviewed and approved by others for applicability and accuracy of the intended use prior to permitting and construction. This office is solely providing a result based on the information you provide to us, that you have affirmed to us is accurate at the time of purchase, and that you have had an opportunity to consult with us prior to use if at all in doubt or have any questions about the use of the document we provided. Information regarding contacting us is provided below.

About Digitally Signed Documents

Digitally signed documents typically contain a disclaimer box limiting the use of the document to a specific contractor with a geographic zip code limitation and approved date range to apply for an electronic permit. Digitally signed documents also contain encryption to verify the authenticity of the document which shall be verified by electronic means by others before use.

Digitally signed documents must remain digital and become invalid for use once printed. Scanned copies of printed digitally sealed plans are no longer considered digital and are invalid for use.

The zip code provided in the disclaimer is provided solely to limit repeated use of the document and is not intended to serve as approval that the purchased document is valid for use within that zip code or any site-specific address contained within. Signed documents may also contain a building floor elevation to which the use is limited to which is requested and provided solely to limit misuse of the signed document. Certification at a specific address and building floor is the responsibility of others as described herein.

The date limitation is intended to limit the amount of time the permittee has to submit the document with the electronic application for permit. The document is valid for use within the limitations and building codes provided on the purchased document.

More information about digitally signed documents can be found by clicking here.

About Physical Printed ‘Hardcopies’

Documents that are physically printed (also known as hard copies) are signed and sealed with an embossed or ‘wet’ ink seal by the certifying design professional. For these documents to be valid for use, the ORIGINAL document must be presented to the approving municipality. PHOTOCOPIES OF PRINTED DOCUMENTS ARE NOT CONSIDERED SIGNED AND SEALED AND ARE NOT VALID FOR USE. This firm is not responsible for the use of any photocopied document of our signed and sealed work.

Additionally, markings or alterations to original signed and sealed documents invalidate our certification and require additional review prior to use.

Each signed and sealed document contains information on how to obtain an originally sealed version.

More information about physically signed documents can be found by clicking here.

About Generic Documents Purchased For Building Components Attached To Structures

Documents purchased for host-attached building components (such as overhangs, wall-mounted signs, and rooftop mechanical equipment) DO NOT certify the building component for use on any specific project. Each of these performance evaluations requires another design professional to review and approve the document for the intended site-specific application including the integrity of the host structure to withstand the additional forces placed by the building component at the time of the worst-case design condition (such as during a hurricane, snowstorm, earthquake, maximum occupancy load, etc). THE DOCUMENTS PURCHASED THROUGH THE ONLINE PLAN STORE OR DOWNLOADED FROM A STATE EVALUATION SITE (SUCH AS MIAMI DADE NOA’S OR FL PRODUCT APROVALS) DO NOT DO THIS. ADDITIONAL STEPS MUST BE TAKEN PRIOR TO PERMITTING AND CONSTRUCTION.

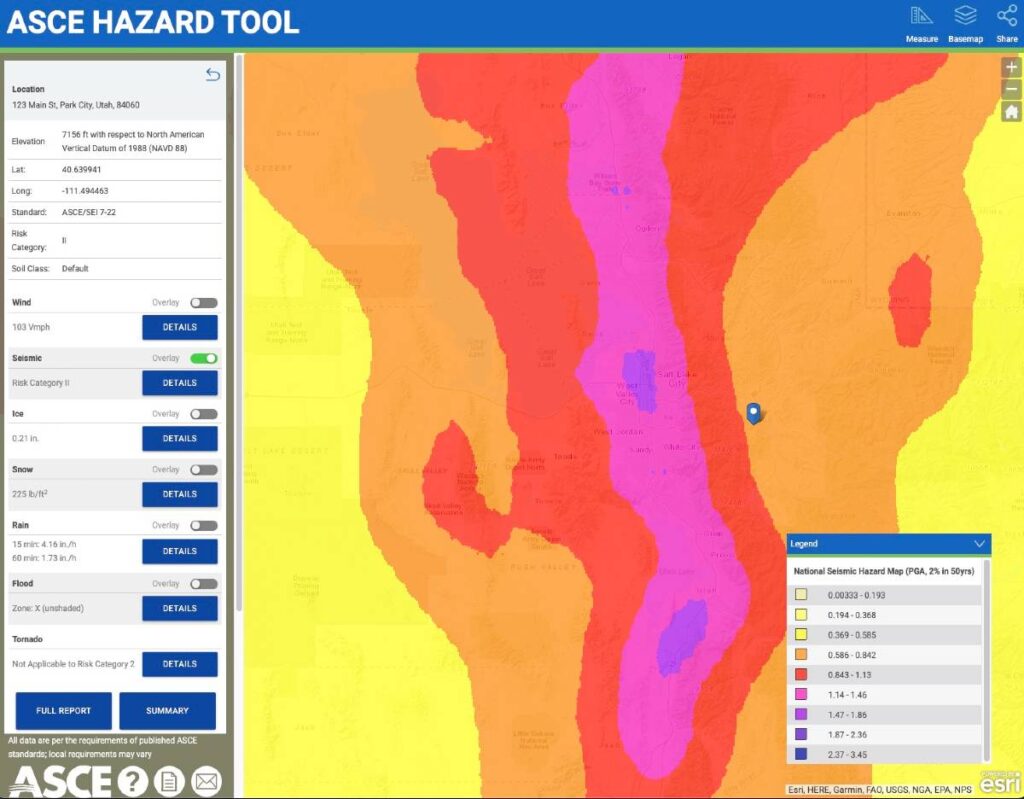

The purchased documents solely state the performance limitation of the building component to the loads and design wind/snow/seismic/forces listed within the evaluation. The actual code-minimum design forces for your site-specific project may be HIGHER than the limitations of the purchased document which shall be determined, reviewed, and approved by others and not part of our certification or your purchase.

The determination of the applicability of the use of the purchased documents is the sole responsibility of others and not purchased or included in the document you obtain from us.

Engineering Express can provide a quotation for these additional site-specific services. Click Here to apply for access to our quoting system to submit a site-specific design request.

About Generic Documents Purchased For Freestanding Building Components

Documents purchased for freestanding building components (such as fences, freestanding pergolas, A/C and generator pads, and ground-mounted signs) contain limitations of their use and may contain equivalent design information (such as wind, snow, geotechnical, and seismic equivalent values). These documents DO NOT approve the use of the building component for YOUR APPLICATION. The documents we provide state that IF your application meets the listed limitations of use, the building component can withstand the imposed code-minimum design forces and limitations as stated on the respective plan.

The determination of the applicability of the use of the purchased documents is the sole responsibility of others and not purchased or included in the document you obtain from us. Engineering Express can provide a quotation for these additional site-specific services. Click Here to apply for access to our quoting system to submit a site-specific design request.

Other:

While any licensed professional can provide the site-specific information required for use with the purchased documents as described herein, this office welcomes the opportunity to quote these additional services for other businesses. Click Here to apply for access to our quoting system to submit a site-specific design request.

Certified documents are only valid for the state, building code, and limitations of use listed in the original, certified document. For use in states and building codes other than listed, contact the office for further evaluation which may require alterations to the performance limitations or review and certification by a licensed professional in the state requested.

Please note that while homeowners may purchase documents from our plan store, we do not perform any consultation services directly with homeowners. If you are a homeowner and purchased certified documents from our plan store, please have your contractor contact us, or work with a local licensed professional to complete your application for permit which shall include their approval for use of your purchased documents for your specific project.

We are not responsible for any installation deficiencies that occur from the misuse of any certified document purchased from us. Any deviations from the specifications in our plans, alterations, or markings to our certified documents or use without consulting a design professional is strictly prohibited and INVALIDATE OUR CERTIFICATION. Use of the purchased documents indemnifies & saves harmless the engineer & firm for all cost & damages including legal & appellate fees resulting from deviations of the certified plan as well as material fabrication, system erection, & construction practices beyond which is called for by local, state, & federal codes and standards of care.

The determination of the applicability of the use of the purchased documents is the sole responsibility of others and is not included in the document you obtain from us. Engineering Express can provide a quotation for these additional site-specific services. Click Here to apply for access to our quoting system to submit a site-specific design request.

Contact this office with any questions or to request a design consultation which is required prior to permitting and construction to ensure proper use of these documents and a safe, code-compliant design.

Tell us how can we improve this post?

How can you leave my order outside in one of your office pickup boxes?

Pickups have been discontinued from all of our Office Locations. Not to worry, we have free local shipping for minimum fee orders and are happy to work with any of our repeat clients on ways to avoid shipping fees for small orders.

Contact us or chat with us online to discuss your express delivery needs on any project or online order.

Tell us how can we improve this post?

I need help finding a tie down detail for permit

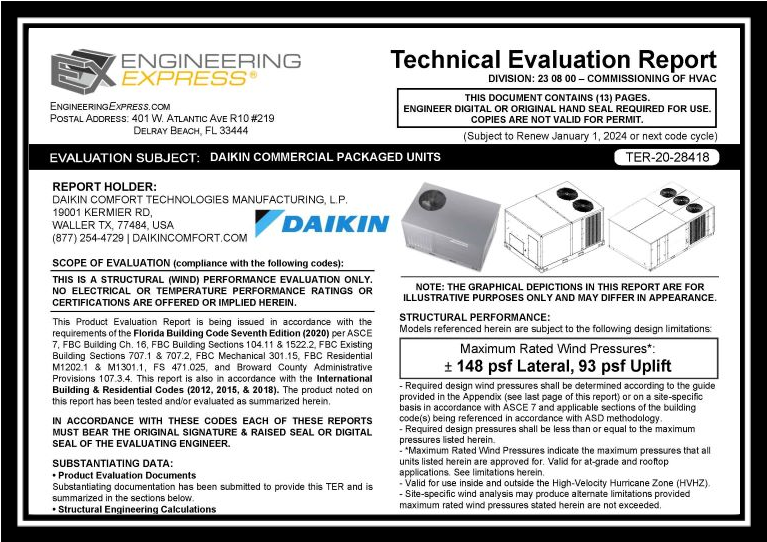

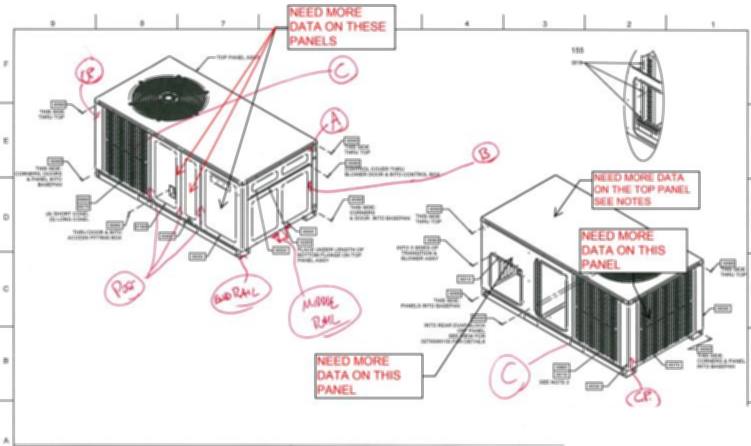

Tie-down details are incorporated into Technical Evaluation Reports (TERs) which are cataloged by model number for manufacturers such as Trane, Carrier, Daikin, Samsung, Mitsubishi, and others.

You can search for tie down details by model number or TER number/name on our mechanical page.

You can also visit EngineeringExpress.com/store to search for the product you need (Begin by the brand needed then select the type of unit).

NOTE: Engineering Express only provides tie-down details for models we are contracted for by the product manufacturers. If you don’t see what you need, you will need to contact the product distributor to locate the tie down detail by their respective engineer.

Tell us how can we improve this post?

How do I know if a payment went through for my online order?

You will get an email to confirm we have received your request once the payment has been approved

Tell us how can we improve this post?

How can clients in the South Florida area save money on shipping fees?

If you are a frequent buyer in the South Florida area, consider merging your orders into a single purchase over $100.00 (Digital and/or hard copies) to qualify for free local shipping (Miami Dade, Broward & Palm Beach counties, Florida)

Tell us how can we improve this post?

is the 6th Edition Florida Building Code still valid? That’s what it says on my plan.

If the controlling permit for your project is dated prior to Jan 1, 2021, then the 6th Edition Florida Building Code is still valid. Otherwise, you will need to place an order for an updated version of the plan (please visit EngineeringExpress.com/store/ to start your search (We recommend beginning with the brand needed if known or project number you have on your outdated plan).

Tell us how can we improve this post?

I need to create an NOA / product approval for my product. What’s the process?

Start by reading our articles about product approvals by Clicking Here. You’ll learn when they’re really needed, what information we need, how they help, and much more.

> In short, products ‘inside the rule‘ require product approval in Florida.

> This is done by a combination of testing & rational analysis as determined by code.

> Most products such as windows, doors, and roofing require extensive testing. From there, the tests can be uploaded to the State of Florida or Evaluated by an engineer. Product Evaluations allow variations such as alternate sizes, substrates, and anchoring.

> Prior to testing, a qualified firm should be retained to establish a test protocol to maximize the use of the test results. That firm needs to be independent of the lab conducting the testing.

> With testing complete, the evaluating engineer would consult with you on the best format to display the evaluation.

> For Florida Product Approvals, prior to submitting to the state, a Validator and Quality Assurance entity needs to be retained to provide the 3rd party assurance that the evaluation is performed per code and the product meets the tested parameters over time.

> After the Florida Approval is granted, the document registration number can be used for permit in Florida if the installation matches the intent of the evaluation report. Typically a local design professional (architect or engineer) is retained to establish the design criteria of the local installation and ‘approve’ the approval for use at that location/opening. Modifications may be permitted if performed within the guidelines of the building code, referenced standards, and the limitations of the evaluation.

You can search Florida & Miami Dade Product Approvals for similar examples of your product for consideration by clicking here.

When you’re ready for Engineering Express to help & have the information gathered in the articles, visit EngineeringExpress.com/ExpressPass to apply for access & request a quote for your product evaluation. We will contact you shortly thereafter to discuss your needs & detail & how our national certifications can help.

Tell us how can we improve this post?

I have a different brand product than the one you specify but it’s similar. How can I get mine certified for permit?

This would require the project to be site specific.

Please visit EngineeringExpress.com/ExpressPass to apply for access to request a quote for a site-specific project.

Click ‘apply for access’, fill the form and in the description box, please give us an idea of the project you are looking for. After submitting a team leader will contact you back with the following steps.

(This process can’t be done by homeowners. We recommend finding a contractor to assist or another local engineer).

Tell us how can we improve this post?

I received a hardcopy (printed) plan and need a digitally signed-sealed file. What do I do?

You will need to place a new order in our online plan store for the same plan but select ‘digitally sealed file’ under the ‘plan format’ option & re-pay for the plan.

If you can return the physical plan we will provide Tokens as credits for additional orders. See our Refund policy for more.

Tell us how can we improve this post?

I’d like to use an EFT (electronic funds transfer) instead of a credit card. Can you help with that?

See our Pay Page or contact our office for more information.

Tell us how can we improve this post?

I placed an order for pickup that now needs to be shipped. What do I do?

Engineering Express discontinued pickup from all of our Office Locations. That option has been removed from our online store in case you are looking for it.

Not to worry, we have free local shipping for minimum fee orders and are happy to work with any of our repeat clients on ways to avoid shipping fees for small orders.

Contact us or chat with us online to discuss your express delivery needs on any project or online order.

Tell us how can we improve this post?

I made a mistake on the zip code of an online digital order. What do I do?

This can only be done if the order has not been processed. Please contact our office for further assistance or use our Live Chat feature.

Tell us how can we improve this post?

How can I cancel an online order?

This can only be done if the order has not been processed or shipped. Please contact our office for further assistance or use our Live Chat feature.

Tell us how can we improve this post?

I ordered a project through E-Tempest. What’s the process for receiving a digitally signed-sealed file?

Engineering Express provides engineering review & certification of orders placed through E-Tempest shutter software. If you ordered the digitally signed and sealed file from E-Tempest, it will be emailed to you as a PDF attachment. If you requested Hard copies but need a digitally signed – sealed file, please contact E-Tempest directly.

Tell us how can we improve this post?

Can I get a discount on volume plan store orders?

Engineering Express has developed an efficient system for volume discounts. Discounts are offered by purchasing Tokens in bulk. This allows volume orders to be spread out over time & products, and also avoids license fee charges.

Visit EngineeringExpress.com/Tokens for more information about our token system and bulk discounts.

Tell us how can we improve this post?

I’m looking for a model not shown on the chart in a Technical Evaluation Report (TER). What do I do?

Engineering Express would love to have every model unit of an A/C or generator pre-engineered. We can only engineer what we’re hired to do by the manufacturer so letting them know is always an option.

If you are a contractor & in need of our help right away, you would need to order a site-specific design so we can process 1 model for 1 address efficiently & inexpensively. Visit EngineeringExpress.com/ExpressPass, to apply for an account & request a quote for a site-specific project.

Click at apply for access, fill the form and in the description box, please give us an idea of the project you are looking for, after submitting a team leader will contact you back with the following steps.

(This process can’t be done by homeowners. We recommend hiring a contractor or calling the manufacturer. We simply cannot handle the volume of homeowner requests with the price point needed & volume of information we need to obtain).

Tell us how can we improve this post?

How can I clarify my account status with Engineering Express?

If you have reason to believe your account is not in good standing, or if a designer tells you they cannot process your work due to your account status, contact our office to help you further with your request by sending an email to [email protected] or using our general Contact Us form.

Tell us how can we improve this post?

How can I confirm you have my current address for shipping?

If you need to change the shipping address of an order already placed, you will need to send an email to [email protected] with your order number & new shipping address before your order gets completed or shipped.

For new orders, be sure to update your information on your Account Page.

Tell us how can we improve this post?

I have a question about project statuses and what DRAFT means

To understand draft & final sealed work, see this article.

Project statuses are mostly self-explanatory throughout ExpressPass & the online ordering system. If you have questions, send us a Live Chat.

Tell us how can we improve this post?

How do I check the project status of my project with Engineering Express?

Use our convenient Status Page to check your order.

If it’s an online order, you can also find the status & track your package on your Dashboard.

For ExpressPass users, log in to ExpressPass & look under ‘orders & quotes’.

Tell us how can we improve this post?

How can I get my digitally signed – sealed file resent to me?

Use the live chat during business hours or use our Contact Form for the most reliable service.

Tell us how can we improve this post?

This is my first time paying for an invoice. How can I pay?

For site-specific (custom) project orders, the fastest way to pay is EngineeringExpress.com/pay. You will need the project, invoice or quote number.

For online orders through our Plan Store, payment is collected at checkout via credit card or PayPal.

Tell us how can we improve this post?

How do I know if my order is ready for pickup?

Engineering Express discontinued pickup from all of our Office Locations.

Not to worry, we have free local shipping for minimum fee orders and are happy to work with any of our repeat clients on ways to avoid shipping fees for small orders.

Contact us or chat with us online to discuss your express delivery needs on any project or online order.

Tell us how can we improve this post?

Subscription Services Offered by Engineering Express

Membership Services Offered by Engineering Express

Subscribe to one of our exclusive industry packages to gain exclusive access to a host of on-demand engineering services including:

Private Calculators

Gain access to our advanced online calculators to help with Aluminum Member Design Package, Ground Mounted Sign Design & Estimating, Canopies & Carports, Decks, Railings, & more.

See our free online calculators as examples of our amazing tools

Or contact us to create a private calculator for you – Engineering design, estimating, takeoffs, budgeting & other useful functions.

Member Discounts on Tokens

Members of our subscription services receive a monthly stipend of tokens to use to purchase certified plans & calculators for purchase as well as premium discounts on token bundles for even more savings.

More About Tokens & Direct Purchasing

Enginering Support Channels

We curate all your engineering needs into one microsite. Link to your Engineering Support Channel from your website – We link back to you for a seamless customer experience.

Benefit from our Live Chat with a designer, private-labeled access to hundreds of helpful articles, & public & private use of calculators, browse & purchase of plans we create for you, and continuously maintained, custom links to product purchasing, dealers, technical data, CAD files, & any other resource you feel fit.

Support channels can link from our website to provide a focused engineering support solution that looks like your site & returns back to the manufacturer’s website.

View our existing channels

Let’s discuss your needs

How It Works

For qualifying companies in one of the industries we service, we set up a plan for you:

1. Engineering Support Only – Fee based on channel size use

2. Subscription Fee Offset – The more Master Plans, Design Aid Calculators or Custom Engineering we design for you & site specific work coming in, the larger discount we offer on Private Calculators & Engineering Support Channels

3. Engineering Tokens – Subscription fees are offset by providing you with Tokens that can also be shared with your customers. Tokens can be used to purchase Master Plans and Certified Calculators.

About Plan Store Tokens

About Engineering Express

Plan Store Tokens

Why Tokens?

Creating a tokens-based system solves a growing list of client pain points:

> Frequent purchasers can now pay once with your credit card instead of every single checkout – Saves time hassle & money:

Previously plan store customers had to buy bulk quantity of a single plan at the same time to get a bulk discount. Clients can now buy tokens in bulk at a discount & easily use them one plan at a time as needed.

> USE TOKENS & SAVE THE 8% LICENCING FEE CHARGED FOR PLANS

> Qualify for promotional credits as they are offered only when paying with tokens

> Tokens do not expire – Eligible refunds can be easily made using tokens

> Tokens are provided as part of our membership packages featuring valuable engineering services.

> Tokens can also be shared with others, allowing easy ways to help your customers, & co-workers order engineering plans & certified calculations.

Watch to learn about purchasing, using, & sharing Tokens

Purchase Token Bundles

10 Tokens

Convenience Pack

$

100

00

- 1-2 Permit Sets

- Save License Fees

Purchase 10

Best for infrequent client – Saves checkout hassle

15 Tokens

Tier 1 Discount

$

142

50

- SAVE 5%

- Save License Fees

Purchase 15

Best if you need occasional master plans for permit

25 Tokens

Tier 2 Discount

$

225

00

- SAVE 10%

- Save License Fees

Purchase 25

Frequent clients save time, hassle & money

50 Tokens

Power Pack

$

400

00

- SAVE 20%

- Save License Fees

Purchase 50

For our power clients – What you’ve been asking for!

Popular

100 Tokens

VIP Premium Discount

$

750

00

- SAVE 25%

- Save License Fees

Purchase 100

Created to support our VIP clients

Need a quick top-off to your existing tokens?

Purchase our 5 Token Top-off Pack

Contact Us to discuss larger volume & special relationship Token purchases

ADDED BENEFIT OF TOKENS:

USE TOKENS & SAVE THE LICENSING FEE CHARGED TO PLANS IN OUR STORE

AN ADDITIONAL SAVINGS OF 8% PER PLAN

Give & Receive Tokens

Another highly requested feature, you can also purchase tokens in bulk and give them to others. This is useful for manufacturers who provide plans to their installers and can purchase sealed copies at a discount, then transfer tokens to their dealers & vendors to order sealed plans for permit as needed at no cost to them. Manufacturers receive large volume discounts on tokens. Contact Us to discuss your need.

Find the Give Tokens option on your token dashboard or Click Here if you are logged in to gift Tokens.

Token Terms & Conditions

– No Refunds are offered on tokens or any store purchases. Any returned plan is offered tokens only for like-kind. Delivery fees are not refunded or credited.

– Tokens never expire.

– Plan store items & prices are subject to change without notice.

– Permits are never guaranteed as part of plan store purchases. Plans are generic in nature & are designed to be entry-level, worst-case scenarios for the limitations listed. The firm specializes in converting master plans to custom-designed site-specific installation engineering for permit & remains available for light support or full consultation & assistance as needed & agreed learn more.

– Master plans are never listed for site specific addresses. Should a ‘site specific’ plan be required after review by the authority having jurisdiction, the firm shall consider a credit refund of the master plan toward the site-specific quotation for work.

– Digitally signed plans are limited to the purchasing contractor, up to 15 day date range, & zip code region.

– Any proof of tampering or misuse of any plan offered by the firm in any way is subject to lockout of client, forfeiting of tokens, and may constitute a criminal violation.

See additional terms & conditions by Clicking Here.

Tell us how can we improve this post?

About Plan Store, Calculators & Membership Services 18

The building department is asking for design wind speed – risk category – exposure – address on my master plan – TER What do I tell them?

In the case of Master Plans and Technical Evaluation Reports, product evaluations, master plans, and technical evaluation reports generally list the limiting pressure forces that the product (building component) can withstand (such as these – click here).

Items such as wind speed, risk category, wind exposure are connected to the site-specific condition the building component is being installed to (per ASCE 7 & the IBC/FBC). We rate the product to a limiting force, a design professional uses these variables at a site-specific location to determine whether the building component is suitable for use in that situation.

There can be many combinations of wind speed, exposure, roof height, terrain, and other factors that determine what the design pressure is. It’s not possible for an evaluation report to list every condition and someone needs to ensure the component is good enough for the intended use.

Typically a site-specific letter by us, an architect working on a project, or another design professional is needed to connect the maximum forces on our report with the area it’s being installed. We can provide a separate quote if you cannot get someone else on the project to provide it for you. Click here to request a quote or Chat With Us.

Click here to read more about master plans and how they are used for site-specific locations.

Tell us how can we improve this post?

How can I suggest a master plan for you to provide in your plan store

You can click here to fill out a form to send us information about a master plan or product evaluation report you would like for us to create for purchase in our plan store.

Tell us how can we improve this post?

How To Use Master Plans – TER’s – Calculator Reports Purchased From Engineering Express

READ BELOW BEFORE USING NON SITE-SPECIFIC PERFORMANCE EVALUATIONS

FROM ENGINEERING EXPRESS FOR YOUR PROJECT

General Information About Non Site-Specific Plans:

Certified Performance Evaluations (also referred to as Master Plans, Generic, or Non Site-Specific Plans) you receive contain a physical or digitally certified engineer seal. They are intended to be used to assist in obtaining a building permit and in constructing the component conveyed in the plan. In all cases using a non-site specific plan, additional documentation is required to serve as approval of use of the purchased document for the intended location. The design professional providing that approval then becomes the responsible party for their use at that location. This additional documentation is provided by others and not part of the purchase of master plans or technical evaluation reports (TER’s) from us.

At no time is construction to be performed without the review and approval by another party of the documents purchased regarding the applicability, limitations of use, and proper selection of plan detail options for the intended installation. In all cases, completed work shall be inspected and approved by others before approval for use including but not limited to the municipality having jurisdiction, architect and/or engineer of record, and permitting contractor which is not our responsibility or part of this purchase.

The documents you purchase from us unless otherwise stated are for sole approval of a pre-engineered, non-site-specific building component subject to the stated limitations of use only and are NOT intended to serve as approval for the construction of any design or installation.

ALSO, AT NO TIME IS ANY PHOTOCOPY OR UNSEALED DOCUMENT TO BE USED OF PLANS FOR PERMIT UNDER ANY CIRCUMSTANCES. BUILDING CODES REQUIRE AN ORIGINAL, CERTIFIED DOCUMENT FOR EACH PERMIT TO BE VALID FOR USE.

Using Certified Master Plans, TER’s & Other Evaluation Reports

The Master Plans & Technical Evaluation Reports (TER) we provide are structural performance evaluations of the subject building component and do not contain a site-specific address. The certification of those documents approves the limitations of use as stated, NOT that the building component can be used at a specific location. That is the responsibility of others as described herein.

THIS ALSO INCLUDES THE USE OF PERFORMANCE EVALUATIONS SUCH AS MIAMI DADE NOA’S, FLORIDA PRODUCT APPROVALS, TEXAS TDI EVALUATIONS, & ICC EVALUATION REPORTS.

The user of the original, certified documents (never photocopies) shall carefully review each detail for applicability to their site-specific condition and gain approval of use for their application by others. Engineering Express remains available for questions via email, online chat, or phone for questions or clarifications of the information within the purchased document and as contained herein which may result in additional engineering consultation fees. Site-specific review and approval and customized & site-specific design plan services are also available which can be performed by this office or another licensed professional.

Using Certified Design Calculator Reports With Addresses Generated By Engineering Express

Printouts from online calculators may come with a site-specific address. It is understood and agreed that the address, as well as all inputted information, is provided by the purchaser at the time of purchase. By agreeing to purchase the document, you understand and affirm that we have not been contracted to a site-specific study, field investigation, or review design plans by others to provide the result you purchased. The site-specific address you provide serves to bind the document to your permit as is required by code and does not constitute that a site-specific or field review has been performed by this firm to authorize their use. The documents also contain information explaining this, as well as the fact that the certified results are to be reviewed by a design professional along with other required construction documents to obtain a permit for construction and use.

The information provided in the purchased document shall at all times be reviewed and approved by others for applicability and accuracy of the intended use prior to permitting and construction. This office is solely providing a result based on the information you provide to us, that you have affirmed to us is accurate at the time of purchase, and that you have had an opportunity to consult with us prior to use if at all in doubt or have any questions about the use of the document we provided. Information regarding contacting us is provided below.

About Digitally Signed Documents

Digitally signed documents typically contain a disclaimer box limiting the use of the document to a specific contractor with a geographic zip code limitation and approved date range to apply for an electronic permit. Digitally signed documents also contain encryption to verify the authenticity of the document which shall be verified by electronic means by others before use.

Digitally signed documents must remain digital and become invalid for use once printed. Scanned copies of printed digitally sealed plans are no longer considered digital and are invalid for use.

The zip code provided in the disclaimer is provided solely to limit repeated use of the document and is not intended to serve as approval that the purchased document is valid for use within that zip code or any site-specific address contained within. Signed documents may also contain a building floor elevation to which the use is limited to which is requested and provided solely to limit misuse of the signed document. Certification at a specific address and building floor is the responsibility of others as described herein.

The date limitation is intended to limit the amount of time the permittee has to submit the document with the electronic application for permit. The document is valid for use within the limitations and building codes provided on the purchased document.

More information about digitally signed documents can be found by clicking here.

About Physical Printed ‘Hardcopies’

Documents that are physically printed (also known as hard copies) are signed and sealed with an embossed or ‘wet’ ink seal by the certifying design professional. For these documents to be valid for use, the ORIGINAL document must be presented to the approving municipality. PHOTOCOPIES OF PRINTED DOCUMENTS ARE NOT CONSIDERED SIGNED AND SEALED AND ARE NOT VALID FOR USE. This firm is not responsible for the use of any photocopied document of our signed and sealed work.

Additionally, markings or alterations to original signed and sealed documents invalidate our certification and require additional review prior to use.

Each signed and sealed document contains information on how to obtain an originally sealed version.

More information about physically signed documents can be found by clicking here.

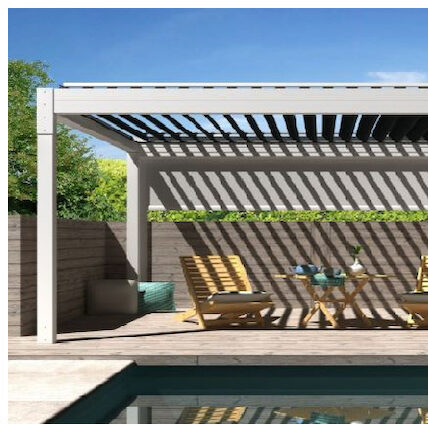

About Generic Documents Purchased For Building Components Attached To Structures

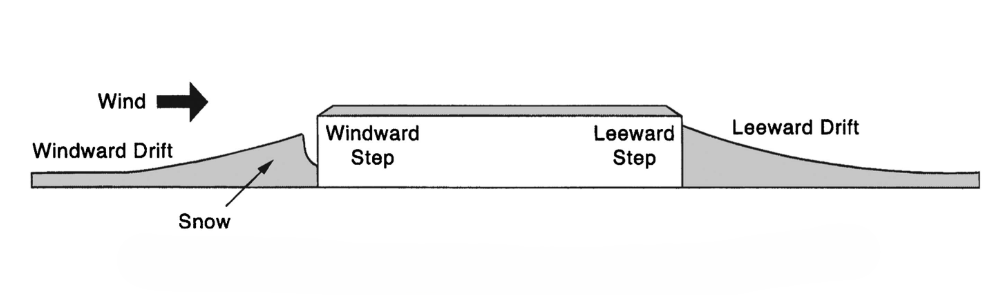

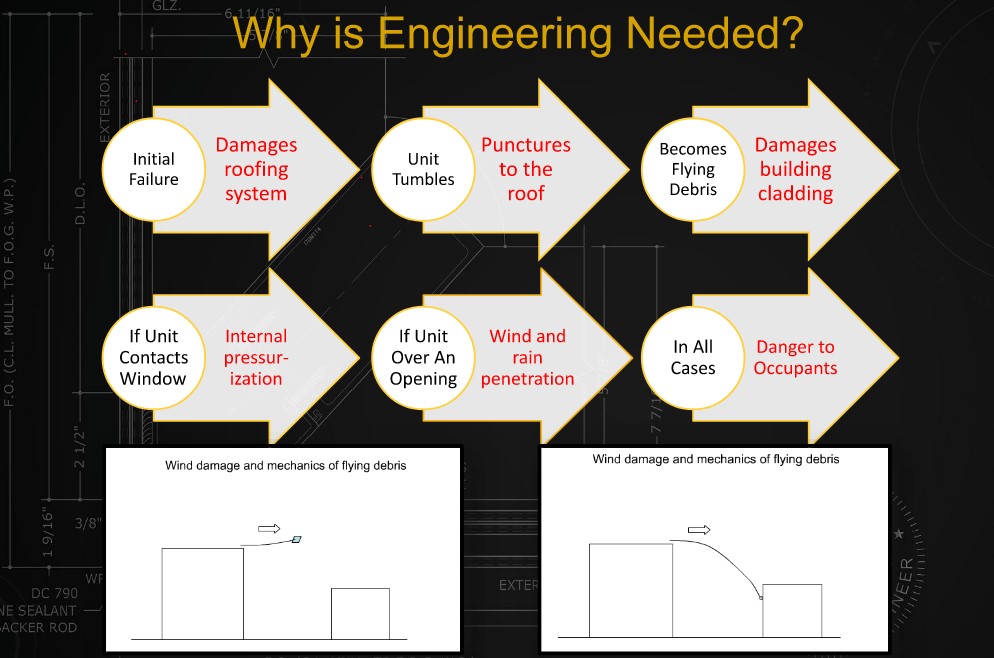

Documents purchased for host-attached building components (such as overhangs, wall-mounted signs, and rooftop mechanical equipment) DO NOT certify the building component for use on any specific project. Each of these performance evaluations requires another design professional to review and approve the document for the intended site-specific application including the integrity of the host structure to withstand the additional forces placed by the building component at the time of the worst-case design condition (such as during a hurricane, snowstorm, earthquake, maximum occupancy load, etc). THE DOCUMENTS PURCHASED THROUGH THE ONLINE PLAN STORE OR DOWNLOADED FROM A STATE EVALUATION SITE (SUCH AS MIAMI DADE NOA’S OR FL PRODUCT APROVALS) DO NOT DO THIS. ADDITIONAL STEPS MUST BE TAKEN PRIOR TO PERMITTING AND CONSTRUCTION.

The purchased documents solely state the performance limitation of the building component to the loads and design wind/snow/seismic/forces listed within the evaluation. The actual code-minimum design forces for your site-specific project may be HIGHER than the limitations of the purchased document which shall be determined, reviewed, and approved by others and not part of our certification or your purchase.

The determination of the applicability of the use of the purchased documents is the sole responsibility of others and not purchased or included in the document you obtain from us.

Engineering Express can provide a quotation for these additional site-specific services. Click Here to apply for access to our quoting system to submit a site-specific design request.

About Generic Documents Purchased For Freestanding Building Components

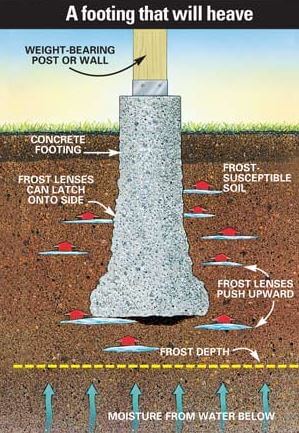

Documents purchased for freestanding building components (such as fences, freestanding pergolas, A/C and generator pads, and ground-mounted signs) contain limitations of their use and may contain equivalent design information (such as wind, snow, geotechnical, and seismic equivalent values). These documents DO NOT approve the use of the building component for YOUR APPLICATION. The documents we provide state that IF your application meets the listed limitations of use, the building component can withstand the imposed code-minimum design forces and limitations as stated on the respective plan.

The determination of the applicability of the use of the purchased documents is the sole responsibility of others and not purchased or included in the document you obtain from us. Engineering Express can provide a quotation for these additional site-specific services. Click Here to apply for access to our quoting system to submit a site-specific design request.

Other:

While any licensed professional can provide the site-specific information required for use with the purchased documents as described herein, this office welcomes the opportunity to quote these additional services for other businesses. Click Here to apply for access to our quoting system to submit a site-specific design request.

Certified documents are only valid for the state, building code, and limitations of use listed in the original, certified document. For use in states and building codes other than listed, contact the office for further evaluation which may require alterations to the performance limitations or review and certification by a licensed professional in the state requested.

Please note that while homeowners may purchase documents from our plan store, we do not perform any consultation services directly with homeowners. If you are a homeowner and purchased certified documents from our plan store, please have your contractor contact us, or work with a local licensed professional to complete your application for permit which shall include their approval for use of your purchased documents for your specific project.

We are not responsible for any installation deficiencies that occur from the misuse of any certified document purchased from us. Any deviations from the specifications in our plans, alterations, or markings to our certified documents or use without consulting a design professional is strictly prohibited and INVALIDATE OUR CERTIFICATION. Use of the purchased documents indemnifies & saves harmless the engineer & firm for all cost & damages including legal & appellate fees resulting from deviations of the certified plan as well as material fabrication, system erection, & construction practices beyond which is called for by local, state, & federal codes and standards of care.

The determination of the applicability of the use of the purchased documents is the sole responsibility of others and is not included in the document you obtain from us. Engineering Express can provide a quotation for these additional site-specific services. Click Here to apply for access to our quoting system to submit a site-specific design request.

Contact this office with any questions or to request a design consultation which is required prior to permitting and construction to ensure proper use of these documents and a safe, code-compliant design.

Tell us how can we improve this post?

I need a wind load chart for window – door – garage door installation. What do I do?

visit This Link on our Plan Store to find wind pressure charts for each of these items.

We also have a site-specific calculator you could use. If you need the answer certified for permit, you can purchase that right on the calculator.

Tell us how can we improve this post?

is the 6th Edition Florida Building Code still valid? That’s what it says on my plan.

If the controlling permit for your project is dated prior to Jan 1, 2021, then the 6th Edition Florida Building Code is still valid. Otherwise, you will need to place an order for an updated version of the plan (please visit EngineeringExpress.com/store/ to start your search (We recommend beginning with the brand needed if known or project number you have on your outdated plan).

Tell us how can we improve this post?

I heard there’s a calculator online that can help me but I can’t find it. What do I do?

You can find all of our public-use calculators here: EngineeringExpress.com/Calculators

Engineering Express also provides calculators to manufacturers & clients through private links & membership platforms. If you feel you are looking for one of these hidden calculators, contact the manufacturer that is sponsoring that tool.

Tell us how can we improve this post?

Can you verify the size of the plan I’m going to receive?

Our technical evaluation reports are formatted to 8.5″x 11″.

The rest of the plans we provide are in 11″ x 17″ (tabloid) format.

Tell us how can we improve this post?

How can I verify prices for an online plan? Your site shows a range of prices.

All of our plans show two prices, the lowest is the price per hard copy (We sell a minimum of 2 copies which is typically requested by building departments & the minimum fee to maintain the site fees).

The higher amount is for the digitally sealed file, which is only provided as a single quantity & discounted due to the savings in processing.

Tell us how can we improve this post?

I made a mistake with an online calculator value. How can that be fixed?

This can only be done if the order has not been processed or shipped. Please contact our office for further assistance or use our Live Chat during business hours.

Tell us how can we improve this post?

I have a technical question on an online plan. Can you help me?

Please email us your question at [email protected] or send us a Live Chat.

Tell us how can we improve this post?

How can I find the sealed wind load chart I’m told I need for permit?

Use This Link for our plan store to select the wall, garage door, or mechanical wind pressure chart you need. Fill in the wind design parameters you need for your wind load chart order based on information provided by your plan reviewer, architectural plans, or your main design professional.

Tell us how can we improve this post?

I have a different size generator than those listed on a concrete pad master plan. How can that be added?

This would require the project to be site specific.

Please visit EngineeringExpress.com/ExpressPass to apply for access to request a quote for a site-specific project.

Click ‘apply for access’, fill the form and in the description box, please give us an idea of the project you are looking for. After submitting a team leader will contact you back with the following steps.

(This process can’t be done by homeowners. We recommend finding a contractor to assist or another local engineer).

Tell us how can we improve this post?

I placed an order for engineering through E-Tempest / one of your online affiliates. How can I find out the status?

Please contact E-tempest directly to know the status of your order.

Tell us how can we improve this post?

I need a wind calculation for a roof. Can Engineering Express help with that?

As of mid-20201 Engineering Express is taking a break from roof designs to focus more on other building components. Visit EngineeringExpress.com/directory/ for a list of S. Florida engineering firms that could help you with your request.

Tell us how can we improve this post?

The Readymade master plan I ordered didn’t solve my need. I need a site-specific. What do I do?

Please see our Refund Policy for information about refunds.

If you would like to discuss your specific issue, please contact us.

Tell us how can we improve this post?

I’m a contractor looking to purchase a fence / gate or similar plan. What do I do?

Engineering Express allows homeowners & contractors to purchase pre-engineered master plans from our Online Plan Store for a number of building component categories.

These plans are sold as-is without refund.

If changes to master plans or custom design work needs to be performed, contractor must be pre-approved to work with us through our ExpressPass application process.

We only engage in work from contractors that perform numerous projects within a given industry in order to best utilize our express engineering process. If you are not approved for this reason, we recommend finding a local engineer or using your current engineer or architect to create custom design based on the plan purchased from Engineering Express.

Tell us how can we improve this post?

I’m a homeowner looking for a fence & gate (or similar) plan for permit. What do I do?

Engineering Express allows homeowners & contractors to purchase pre-engineered master plans from our Online Plan Store for a number of building component categories.

These plans are sold as-is without refund.

Engineering Express does not engage in customizations for pre-engineered plans with homeowners. If changes to master plans or custom design work needs to be performed, we recommend homeowners get with a licensed contractor and work through a local engineer to help with their need. Due to the nature of our setup, we cannot engage in one-time projects for clients.

For Engineering Express to assist in a custom project, a contractor must be pre-approved to work with us through our ExpressPass application process.

We only engage in work from contractors that perform numerous projects within a given industry in order to best utilize our express engineering process. If you are not approved for this reason, we recommend finding a local engineer or using your current engineer or architect to create custom design based on the plan purchased from Engineering Express.

Tell us how can we improve this post?

Instructions for proper use of rooftop equipment wind pressure calculator

HELP PAGE For the Engineering Express®

Rooftop Equipment Wind Pressure Calculator

Note: See Limitations & Conditions of Use at the end of this article.

Quick Links

Access The Calculator

View The Glossary

Learn Even More

Calculator Inputs

1) Ultimate Wind Velocity (Vult): This is the peak 3-second Ultimate gust wind speed. Consult your building department or engineer for governing codes. For more information on what wind speed to use for your project, click here or visit our Knowledgebase and search ‘wind speed’.

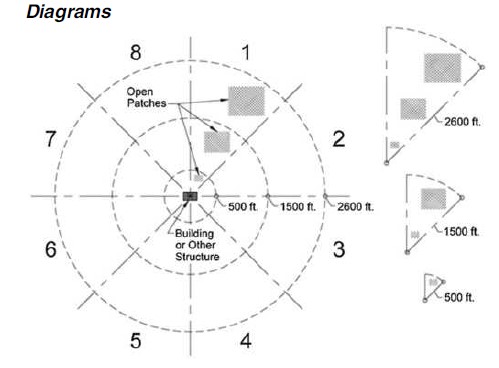

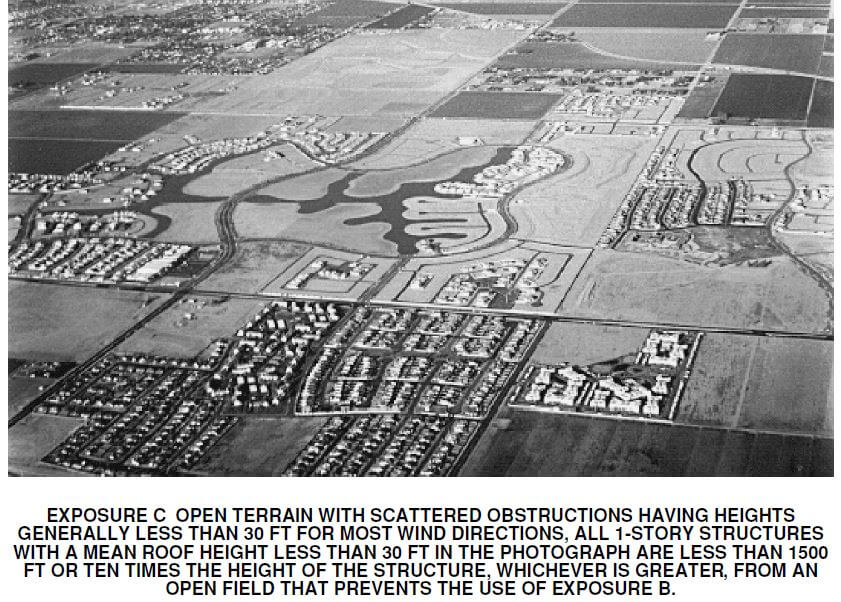

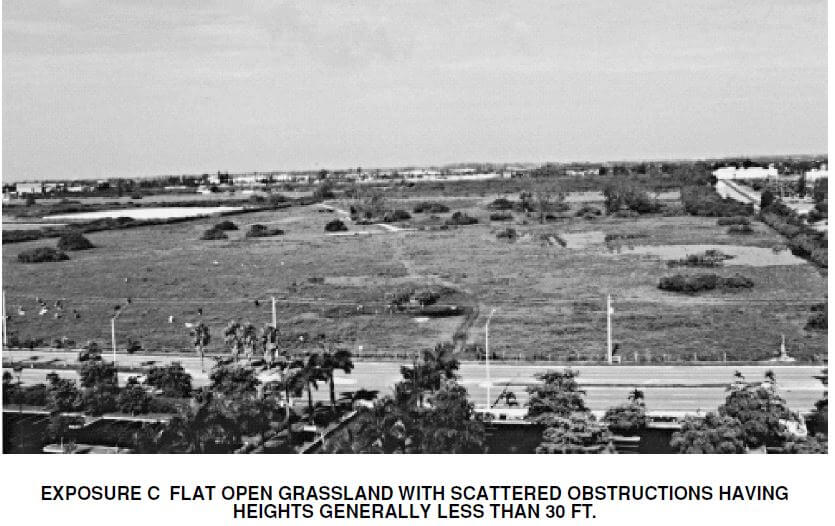

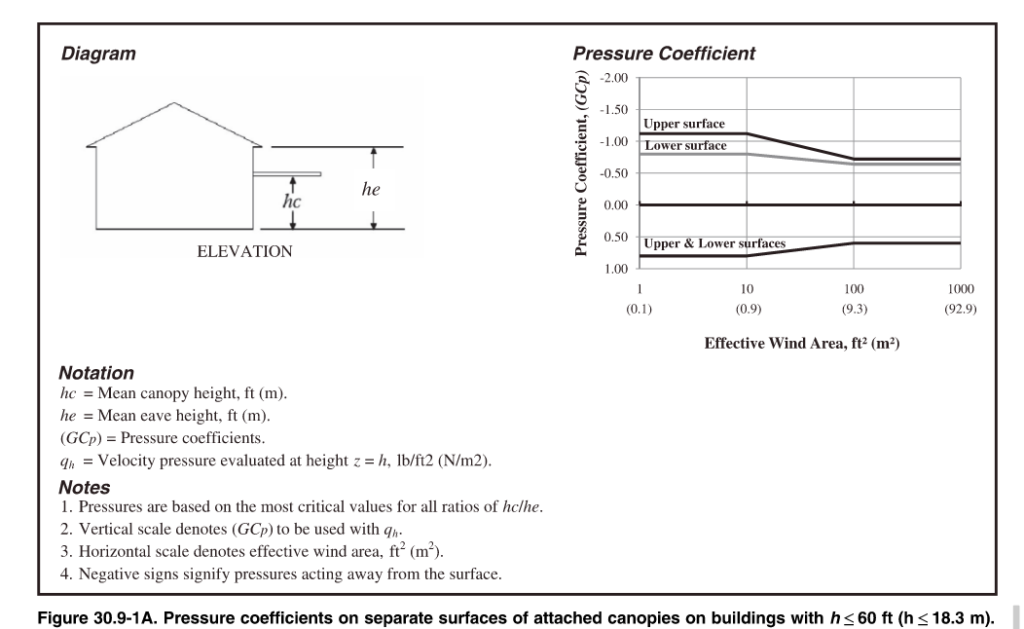

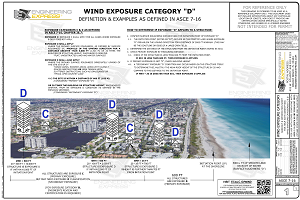

2) ASCE Exposure Category: A terrain classification based on the amount of wind obstacles and ground surface roughness due to natural topography, vegetation, and constructed facilities.

As a general rule:

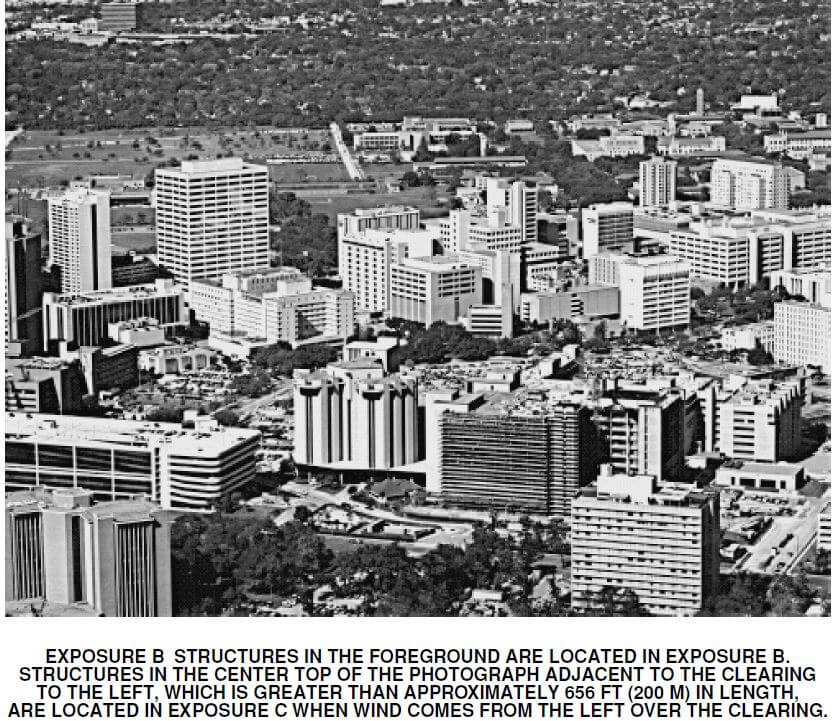

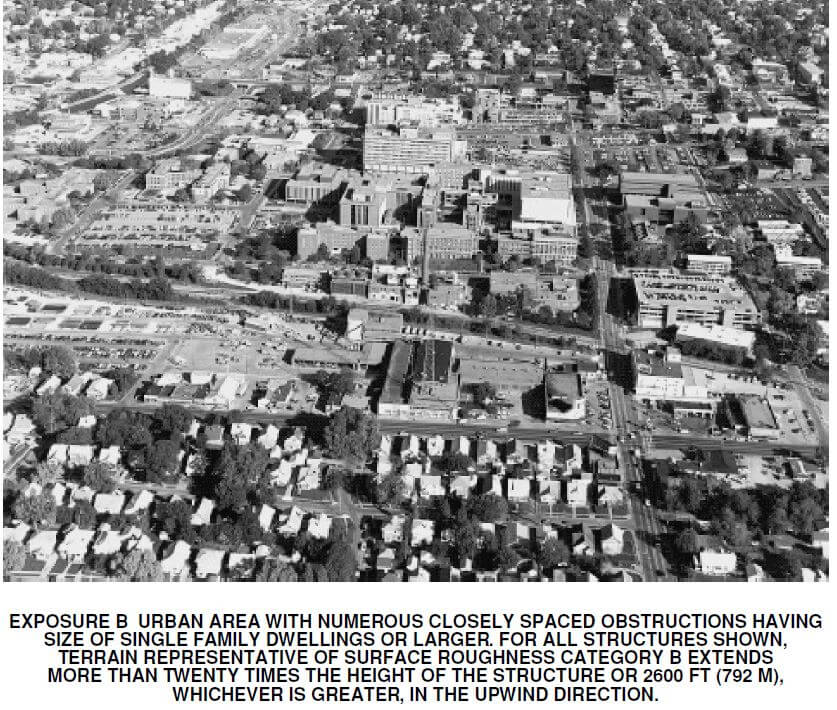

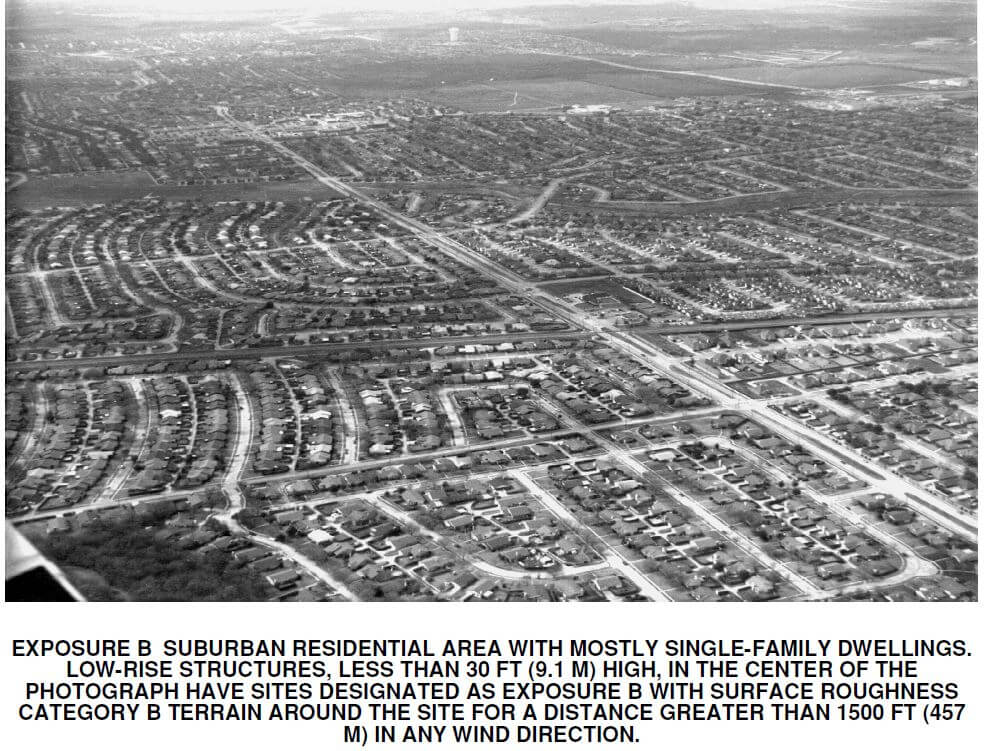

– Exposure Category ‘B’ applies to urban/suburban areas, wooded areas, or other terrain with numerous, closely-spaced obstructions (trees, buildings, etc.).

– Exposure Category ‘C’ applies to open terrain with scattered obstructions, such as flat, open country or grasslands. If in doubt between Exposure Categories ‘B’ or ‘C’, should be used.

– Exposure Category ‘D’ applies to flat, unobstructed areas and water surfaces. It is typically used for coastline regions, as well as for sites near smooth mud flats, salt flats, and unbroken ice.

For more information on exposure categories, Click Here or visit EngineeringExpress.com/Exposures

3) Mean Roof Height (MRH): This is the average roof height between the peak and eave of the roof. If roof is flat (0° slope), MRH is height from ground to roof level, or simply, the height of the building. For more information, click here or visit our knowledgebase and search ‘roof height’.

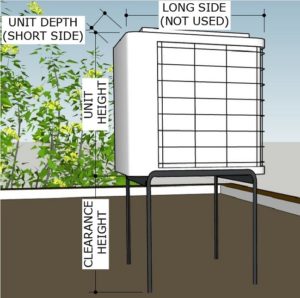

4) Input Unit Information: # of Units: This is the number of unique & separate (not on the same stand) rooftop units being installed at a particular site location. The calculator allows up to a maximum of 5 unique units be included as part of the “Order Certified Results” functionality. The calculator default is 1 unique unit. To change the # of units, simply select from the dropdown the number of unique units being installed at the particular site.

If multiple of the same unit are being installed at a particular site location, the unit information need only be inputted once so long as the clearance height is the same for each unit. If clearance height varies, you will need to input the unit information again with the different clearance height(s) to ensure the wind pressure calculations are accurate.

5) Name / Model #: Input the name or model number of the particular rooftop unit. This is a mandatory field, but does not affect wind pressure calculations. Name / model number is used to easily identify the unit during review by a building department official or third-party reviewer.

6) Unit Depth: This is defined as the smallest horizontal unit dimension (i.e. the lesser of unit width and depth). In other words, the length of the shortest unit side. Note: Unit depth does not affect wind pressure calculations. Unit depth is only considered when determining the minimum required clearance height for your unit for sites located in Florida.

7) Unit Height: This is defined as the height from the bottom of the unit to top of the unit. Refer to manufacturer documentation for unit height.

8) Clearance Height: This is defined as the support structure clear height, or height from roof level to the bottom of the unit. This is typically the height provided by a curb or roof stand.

For sites in Florida, there is a minimum required clearance height based on unit depth (shorter dimension). The calculator will display the minimum required clearance height based on the unit depth you input. Exceptions exist to this requirement which may permit the Authority Having Jurisdiction (AHJ) to allow a lesser minimum required clearance height than what the calculator displays; because of these exceptions, we recommend checking with the AHJ for the final verdict on whether your support structure’s clearance height meets the minimum required clearance height. To allow for these exceptions, you may input any clearance height as an input.

*NOTE: For sites in Florida and outside of Broward and Dade Counties, and if your support structure is a curb, the minimum clearance is 8” per FBCB 1510.10. (In this scenario, ignore the calculator’s displayed minimum clearance). For all other Florida scenarios, follow the calculator’s suggested minimum clearance unless the AHJ permits an exception (check with the AHJ for the final verdict on allowable clearance height).

For more information on minimum required clearance height in Florida, see ecalc.io/clearances.

With all required input fields filled out, output wind pressures will be displayed. The option to “Order Certified Results” will also appear at the top and bottom of the calculator. Click either button to proceed to the order page. Calculator will report if any input fields are not valid. Follow calculator error message as directed to obtain wind pressures and have a professional engineer review and provide certified results for permit.

You will receive a signed and sealed hard copy or digitally signed copy of the results after they are reviewed by design professionals on staff. Results are intended to be used as the structural portion which along with your other documentation to obtain a building permit which is to be inspected by others for final approval.

Fees are listed on the checkout page and may vary. Discounts for frequent use are available through our tokens system.

Glossary

To see a full glossary of terminology used in this calculator and Help Guide, click here for our full glossary or search for the glossary in our knowledgebase.

Explanation of Calculations

Calculations performed by this calculator are as described on the following page:

Lateral Wind Pressure: ASCE 7-16 References

Fh,ult = (qh)(GCr)(Af) (ASCE 7-16, 29.4-1, p. 322)

DPh,ult = Fh,ult / Af = (qh)(GCr) (ASCE 7-16, 30.10, p. 380)

“qh = qz using Kz at Mean Roof Height h” (ASCE 7-16, 26.10.2, p. 268)

qz = 0.00256(Kz)(Kzt)(Kd)(Ke)(V2) psf (ASCE 7-16, 26.10-1, p. 268)

Kz is based on height z in ft and the equation/table specified right: (ASCE 7-16, 26.10.2, p. 268 & Table 26.11-1, p. 269)

z is taken as height of unit centroid above roof level: z = h + (Clearance Height) + (Unit Height / 2)

Kzt is 1.0 for sites located on flat terrain (ASCE 7-16, 26.8.2, p. 267-268)

Kd is 0.85 for rooftop equipment (ASCE 7-16, Table 26.6-1, p. 266)

Ke is 1.0 for site elevations at sea-level. Applicable for all other sites. (ASCE 7-16, Table 26.9-1, p. 268)

V = ultimate wind speed, Vult, in miles per hour (ASCE 7-16, 26.5.1, p. 249)

GCr = 1.9 for lateral wind pressure (worst-case) (ASCE 7-16, 29.4-1, p. 322)

DPh,ASD = ± DPh,ult x 0.6 (ASCE 7-16, 2.4.1, p. 8)

“The [lateral] pressure shall be considered to act inward and outward.” (ASCE 7-16, 30.10, p. 380)

Uplift Wind Pressure:

Fv,ult = (qh)(GCr)(Af) (ASCE 7-16, 29.4-1, p. 322)

DPv,ult = Fv,ult / Af = (qh)(GCr) (ASCE 7-16, 30.10, p. 380)

(Same qh as calculated above for lateral wind pressures) (ASCE 7-16, 29.4-1, p. 322)

GCr = 1.5 for uplift wind pressure (worst-case) (ASCE 7-16, 29.4-1, p. 322)

DPv,ASD = ± DPv,ult x 0.6 (ASCE 7-16, 2.4.1, p. 8)

“The [upward] pressure shall be considered to act in the upward direction.” (ASCE 7-16, 30.10, p. 380)

Examples:

Example 1: Unit Mount to Roof Stand

Input Unit Information:

You are installing (3) of the same unit for this project, but they are each being mounted to a roof stand of the same height: # of Units = 1.

You input the model number for your unit. The unit width is 55.8 in. The unit height is 47.3 in.

The clearance height is the same as stand height: 34 in. (This satisfies Florida’s minimum required clearance height of 30in for a 55.8in wide unit).

Output Wind Pressures:

You should obtain ASD wind pressures of: ± 123.0 psf lateral and 97.1 uplift. The “Order Certified Results” button will appear if you would like to order these results to submit to a building department for permit.

Example 2: Unit Mount to Roof Curb

Let us assume we are installing the condition shown above: a rooftop unit mounting to a steel roof curb. The site is a 140 ft tall office building with a flat roof in Deerfield Beach, Florida. The site is a few miles inland from the coastline. The building has a road with other buildings on the south end, medium-sized parking lots (~100 cars per lot) on the east and west ends, and a grassy field on the north end.

The unit in question is a 28.7in tall, 35.5in wide, and 30in deep. The roof curb is 20in tall. What should we input to the calculator, and what should the calculator output?

Input Site-Specific Conditions:

Upon contacting the Broward County building department or engineer, you are advised to use 175 mph as your Vult.

The Exposure varies between categories B and C depending on the wind direction (if wind approaches from the south end, it would classify as Exposure B. If from the north end, it would classify as Exposure C. For the east and west ends, it could be justified as either Exposures B or C depending on the size of the parking lot and interpretation of the engineer/reviewing party). In order to ensure Exposure category is accepted without question, it is recommended to select Exposure Category C.

For a building with a flat roof, the mean roof height is equal to the building height: 140 feet.

Input Unit Information:

You are installing (2) of the same unit for this project, mounted to roof curbs of equal height: # of Units = 1.

You input the model number for the unit. The unit width is 35.5 in. The unit height is 28.7 in.

The clearance height is the same as stand height: 20 in. (This satisfies Florida’s minimum required clearance height of 18 in for a 35.5 in wide unit).

Output Wind Pressures:

You should see the ASD (Allowable Stress Design) wind pressures of: ± 103.7psf lateral and 81.9 uplift. The “Order Certified Results” button will appear if you would like to order these results to submit to a building department for permit.

Limitations & Conditions of Use

NO WORK SHALL BE CONSIDERED VALID FOR USE WITHOUT THE REVIEW AND CERTIFICATION BY A LICENSED DESIGN PROFESSIONAL.

THIS DOCUMENT & CALCULATOR ARE GUIDANCE ONLY FOR ESTIMATING, ASSISTING DESIGN PROFESSIONALS, & ESTABLISHING COMMUNICATION WITH CODE-COMPLIANT UNIFORMITY IN THIS FIELD.

» It is on the user of this calculator to ensure support structure height meets the required FBC minimum clearance height if the site is located in Florida. For more information, click here or visit ecalc.io/clearances.

» The “Rooftop Equipment Wind Pressure Calculator” produces allowable stress design (ASD) wind pressures based on ASCE 7-16, Section 29.4.1: Rooftop Structures and Equipment for Buildings, and is in accordance with the Florida Building Code Seventh Edition (2020) and International Building Codes 2015 & 2018. Results are also valid for ASCE 7-10, Florida Building Code Sixth Edition (2017), and International Building Code 2012.

» Design pressure results are in accordance with the codes and standards listed above and are applicable for rooftop equipment only.

» The following structures are not permissible for use with this calculator: Solid freestanding walls and signs, open signs, buildings, roofs, domes, chimneys, tanks, solar panels, and ground-mounted equipment. For these installations, please consult our other Design Aid Calculators or contact this office.

» Sample rooftop equipment that are permissible for use with this calculator include: mini-split units, packaged units, VRF units, generator enclosures, commercial chillers, and other split systems / mechanical equipment. Wall-mounted equipment mentioned prior that is mounted greater than 15 ft above grade are also permissible.

» Results are based on client-supplied data and are not field-verified by this office. Results are only valid with original or verifiable digital seal by a licensed Professional Engineer of this firm. Site-specific conditions and unit information shall be verified by others prior to permit and use. Selection of units’ respective product approval(s) shall be by others. Product approval(s) shall provide a performance rating capable of withstanding the ASD design pressures stated herein.

» ASD wind pressures produced by this calculator consider only the wind component of loading on the equipment. Other loading such as dead load is not considered. To consider full ASD load combinations as specified by ASCE 7-16 Section 2.4 and FBCB 2020 Section 1605.3, other loading considerations in addition to the calculated wind pressures will need to be considered.

Ultimate wind pressures may be obtained by dividing the allowable stress design (ASD) wind pressures given by this calculator by 0.6. Akin to above, full ultimate load combinations are not considered. Ultimate wind pressures derived by the stated method accounts only for the worst-case wind component of loading.

» Except as expressly provided herein, no additional certifications or affirmations are intended by use of this calculator or instructions contained herein.

» This calculator is for estimating purposes only and NOT for permit use. Results are only valid when reviewed, signed, and sealed by a Professional Engineer from Engineering Express. Click “Order Certified Results” in the filled-out calculator page to order a review and certification delivered to you for permit.

» In order for calculations to be valid:

- Mean Roof Height shall be between 15 ft (the minimum) & 700 ft.

- The building upon which the unit(s) are installed shall be situated on flat terrain. (Buildings in the immediate vicinity of hills, ridges, or escarpments are subject to different wind load calculations).

» *Florida only: Per FBCB Sections 1510.10 & 1522.3, roof-mounted equipment must be provided the minimum required clearance height based upon the unit’s width (i.e. longest side of unit) and whether or not the unit is located within/outside the High-Velocity Hurricane Zone. For more information, see: https://ecalc.io/clearances

» Please consider all above conditions before using this calculator.

Tell us how can we improve this post?

About Digital & Hardcopy-Sealed Engineering Work 18

Search our AC model Database

Click Here to access our model database tool. You can filter by your AC brand, model, and number to find the TER report you need to purchase for permit.

Tell us how can we improve this post?

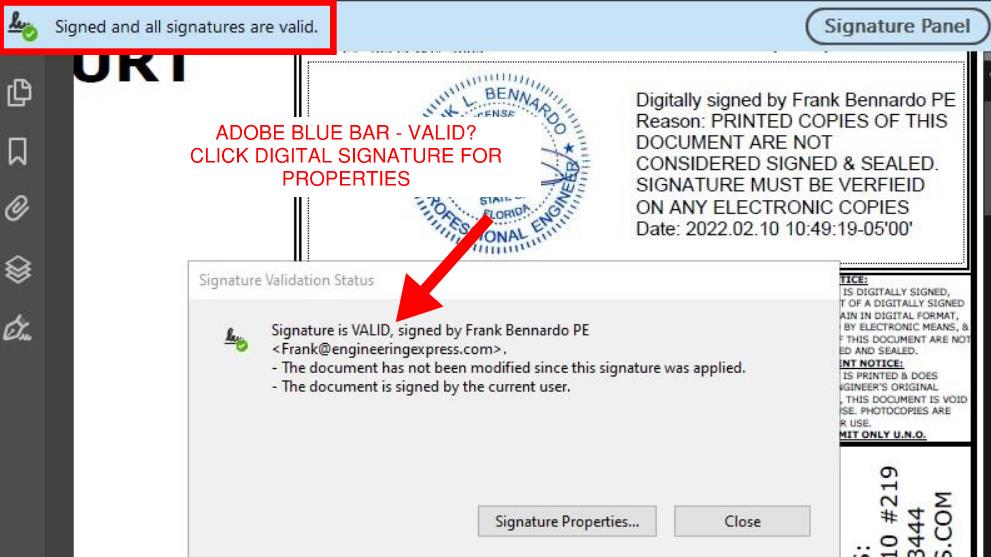

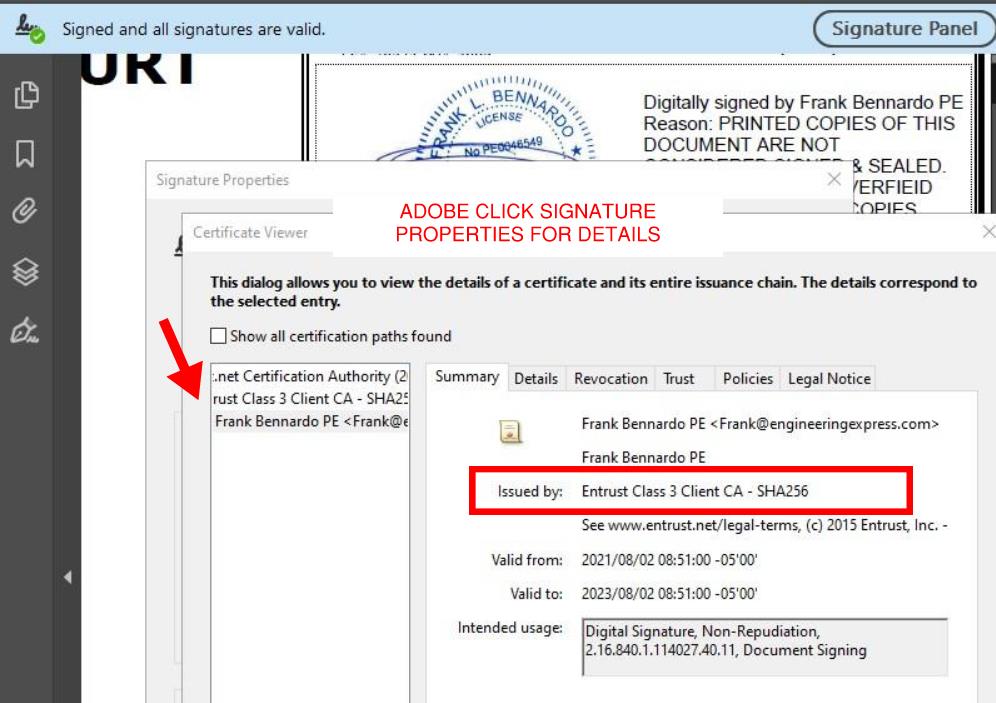

How To Validate A Digital Signature On An Engineers Digitally-Sealed Plan

Digital signatures for engineers in Florida require third-party validation per FAC 61G15-23.004. Other states offer similar rules that require the signature to be verifiable to which this also applies.

Here’s how to check a digitally signed document in Adobe & Bluebeam to ensure the signature is valid.

How To Verify In Adobe

A digitally signed document in Adobe Reader or their Pro DC version will show a blue bar up top.

Method 1: That bar will indicate whether the document is VALID, Invalid, or needs verification. If it doesn’t say valid, try method 2 below. If neither prove verifiable, the document was either modified or was not properly digitally signed in the first place.

Method 2: Click the digital signature and the verification box will appear. That box will show details of whether or not the signature is valid.

If you click the ‘Signature Properties’ button within that dialog box, you’ll see additional information about the signature such as the third party that is validating the signature (in this case it’s Entrust.

Learn more about Adobe digital signature verification from their website by clicking here.

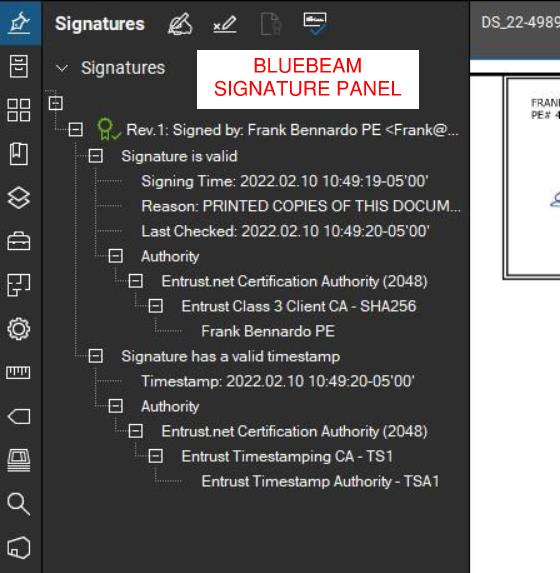

How To Verify in Bluebeam

Verifying a digitally signed document in Bluebeam is similar but not as obvious as Adobe. No blue bar appears but there are 2 ways of verifying:

Method 1: Right Click The Digital Signature and select ‘properties’ to reveal the signature properties:

Method 2: Use the Information Panel – to show the signature panel in Bluebeam, go to Window > Panels > Signature OR press Alt+4. if the current document has been digitally signed, it will show as per the below in the signature panel:

Learn more about how to verify digital signatures in Bluebeam by clicking here.

For more information about digital & electronic signatures from our Knowledge Base, click here.

Tell us how can we improve this post?

How To Use Master Plans – TER’s – Calculator Reports Purchased From Engineering Express

READ BELOW BEFORE USING NON SITE-SPECIFIC PERFORMANCE EVALUATIONS

FROM ENGINEERING EXPRESS FOR YOUR PROJECT

General Information About Non Site-Specific Plans:

Certified Performance Evaluations (also referred to as Master Plans, Generic, or Non Site-Specific Plans) you receive contain a physical or digitally certified engineer seal. They are intended to be used to assist in obtaining a building permit and in constructing the component conveyed in the plan. In all cases using a non-site specific plan, additional documentation is required to serve as approval of use of the purchased document for the intended location. The design professional providing that approval then becomes the responsible party for their use at that location. This additional documentation is provided by others and not part of the purchase of master plans or technical evaluation reports (TER’s) from us.

At no time is construction to be performed without the review and approval by another party of the documents purchased regarding the applicability, limitations of use, and proper selection of plan detail options for the intended installation. In all cases, completed work shall be inspected and approved by others before approval for use including but not limited to the municipality having jurisdiction, architect and/or engineer of record, and permitting contractor which is not our responsibility or part of this purchase.

The documents you purchase from us unless otherwise stated are for sole approval of a pre-engineered, non-site-specific building component subject to the stated limitations of use only and are NOT intended to serve as approval for the construction of any design or installation.

ALSO, AT NO TIME IS ANY PHOTOCOPY OR UNSEALED DOCUMENT TO BE USED OF PLANS FOR PERMIT UNDER ANY CIRCUMSTANCES. BUILDING CODES REQUIRE AN ORIGINAL, CERTIFIED DOCUMENT FOR EACH PERMIT TO BE VALID FOR USE.

Using Certified Master Plans, TER’s & Other Evaluation Reports

The Master Plans & Technical Evaluation Reports (TER) we provide are structural performance evaluations of the subject building component and do not contain a site-specific address. The certification of those documents approves the limitations of use as stated, NOT that the building component can be used at a specific location. That is the responsibility of others as described herein.

THIS ALSO INCLUDES THE USE OF PERFORMANCE EVALUATIONS SUCH AS MIAMI DADE NOA’S, FLORIDA PRODUCT APPROVALS, TEXAS TDI EVALUATIONS, & ICC EVALUATION REPORTS.

The user of the original, certified documents (never photocopies) shall carefully review each detail for applicability to their site-specific condition and gain approval of use for their application by others. Engineering Express remains available for questions via email, online chat, or phone for questions or clarifications of the information within the purchased document and as contained herein which may result in additional engineering consultation fees. Site-specific review and approval and customized & site-specific design plan services are also available which can be performed by this office or another licensed professional.

Using Certified Design Calculator Reports With Addresses Generated By Engineering Express

Printouts from online calculators may come with a site-specific address. It is understood and agreed that the address, as well as all inputted information, is provided by the purchaser at the time of purchase. By agreeing to purchase the document, you understand and affirm that we have not been contracted to a site-specific study, field investigation, or review design plans by others to provide the result you purchased. The site-specific address you provide serves to bind the document to your permit as is required by code and does not constitute that a site-specific or field review has been performed by this firm to authorize their use. The documents also contain information explaining this, as well as the fact that the certified results are to be reviewed by a design professional along with other required construction documents to obtain a permit for construction and use.

The information provided in the purchased document shall at all times be reviewed and approved by others for applicability and accuracy of the intended use prior to permitting and construction. This office is solely providing a result based on the information you provide to us, that you have affirmed to us is accurate at the time of purchase, and that you have had an opportunity to consult with us prior to use if at all in doubt or have any questions about the use of the document we provided. Information regarding contacting us is provided below.

About Digitally Signed Documents

Digitally signed documents typically contain a disclaimer box limiting the use of the document to a specific contractor with a geographic zip code limitation and approved date range to apply for an electronic permit. Digitally signed documents also contain encryption to verify the authenticity of the document which shall be verified by electronic means by others before use.

Digitally signed documents must remain digital and become invalid for use once printed. Scanned copies of printed digitally sealed plans are no longer considered digital and are invalid for use.

The zip code provided in the disclaimer is provided solely to limit repeated use of the document and is not intended to serve as approval that the purchased document is valid for use within that zip code or any site-specific address contained within. Signed documents may also contain a building floor elevation to which the use is limited to which is requested and provided solely to limit misuse of the signed document. Certification at a specific address and building floor is the responsibility of others as described herein.

The date limitation is intended to limit the amount of time the permittee has to submit the document with the electronic application for permit. The document is valid for use within the limitations and building codes provided on the purchased document.

More information about digitally signed documents can be found by clicking here.

About Physical Printed ‘Hardcopies’

Documents that are physically printed (also known as hard copies) are signed and sealed with an embossed or ‘wet’ ink seal by the certifying design professional. For these documents to be valid for use, the ORIGINAL document must be presented to the approving municipality. PHOTOCOPIES OF PRINTED DOCUMENTS ARE NOT CONSIDERED SIGNED AND SEALED AND ARE NOT VALID FOR USE. This firm is not responsible for the use of any photocopied document of our signed and sealed work.

Additionally, markings or alterations to original signed and sealed documents invalidate our certification and require additional review prior to use.

Each signed and sealed document contains information on how to obtain an originally sealed version.

More information about physically signed documents can be found by clicking here.

About Generic Documents Purchased For Building Components Attached To Structures

Documents purchased for host-attached building components (such as overhangs, wall-mounted signs, and rooftop mechanical equipment) DO NOT certify the building component for use on any specific project. Each of these performance evaluations requires another design professional to review and approve the document for the intended site-specific application including the integrity of the host structure to withstand the additional forces placed by the building component at the time of the worst-case design condition (such as during a hurricane, snowstorm, earthquake, maximum occupancy load, etc). THE DOCUMENTS PURCHASED THROUGH THE ONLINE PLAN STORE OR DOWNLOADED FROM A STATE EVALUATION SITE (SUCH AS MIAMI DADE NOA’S OR FL PRODUCT APROVALS) DO NOT DO THIS. ADDITIONAL STEPS MUST BE TAKEN PRIOR TO PERMITTING AND CONSTRUCTION.

The purchased documents solely state the performance limitation of the building component to the loads and design wind/snow/seismic/forces listed within the evaluation. The actual code-minimum design forces for your site-specific project may be HIGHER than the limitations of the purchased document which shall be determined, reviewed, and approved by others and not part of our certification or your purchase.

The determination of the applicability of the use of the purchased documents is the sole responsibility of others and not purchased or included in the document you obtain from us.

Engineering Express can provide a quotation for these additional site-specific services. Click Here to apply for access to our quoting system to submit a site-specific design request.

About Generic Documents Purchased For Freestanding Building Components

Documents purchased for freestanding building components (such as fences, freestanding pergolas, A/C and generator pads, and ground-mounted signs) contain limitations of their use and may contain equivalent design information (such as wind, snow, geotechnical, and seismic equivalent values). These documents DO NOT approve the use of the building component for YOUR APPLICATION. The documents we provide state that IF your application meets the listed limitations of use, the building component can withstand the imposed code-minimum design forces and limitations as stated on the respective plan.

The determination of the applicability of the use of the purchased documents is the sole responsibility of others and not purchased or included in the document you obtain from us. Engineering Express can provide a quotation for these additional site-specific services. Click Here to apply for access to our quoting system to submit a site-specific design request.

Other:

While any licensed professional can provide the site-specific information required for use with the purchased documents as described herein, this office welcomes the opportunity to quote these additional services for other businesses. Click Here to apply for access to our quoting system to submit a site-specific design request.